Publications

2026

- ICLR 2026

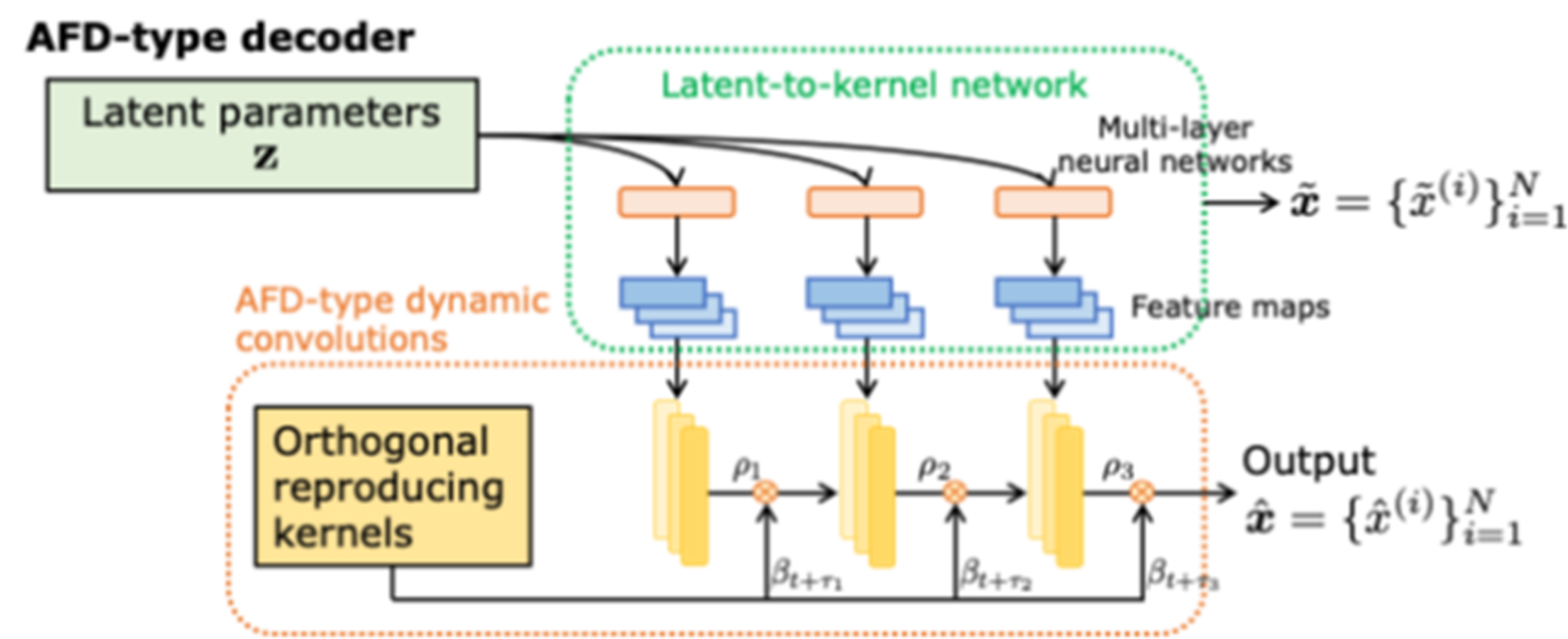

Adaptive Mamba Neural OperatorsZeyuan Song and Zheyu JiangIn The Fourteenth International Conference on Learning Representations, 2026

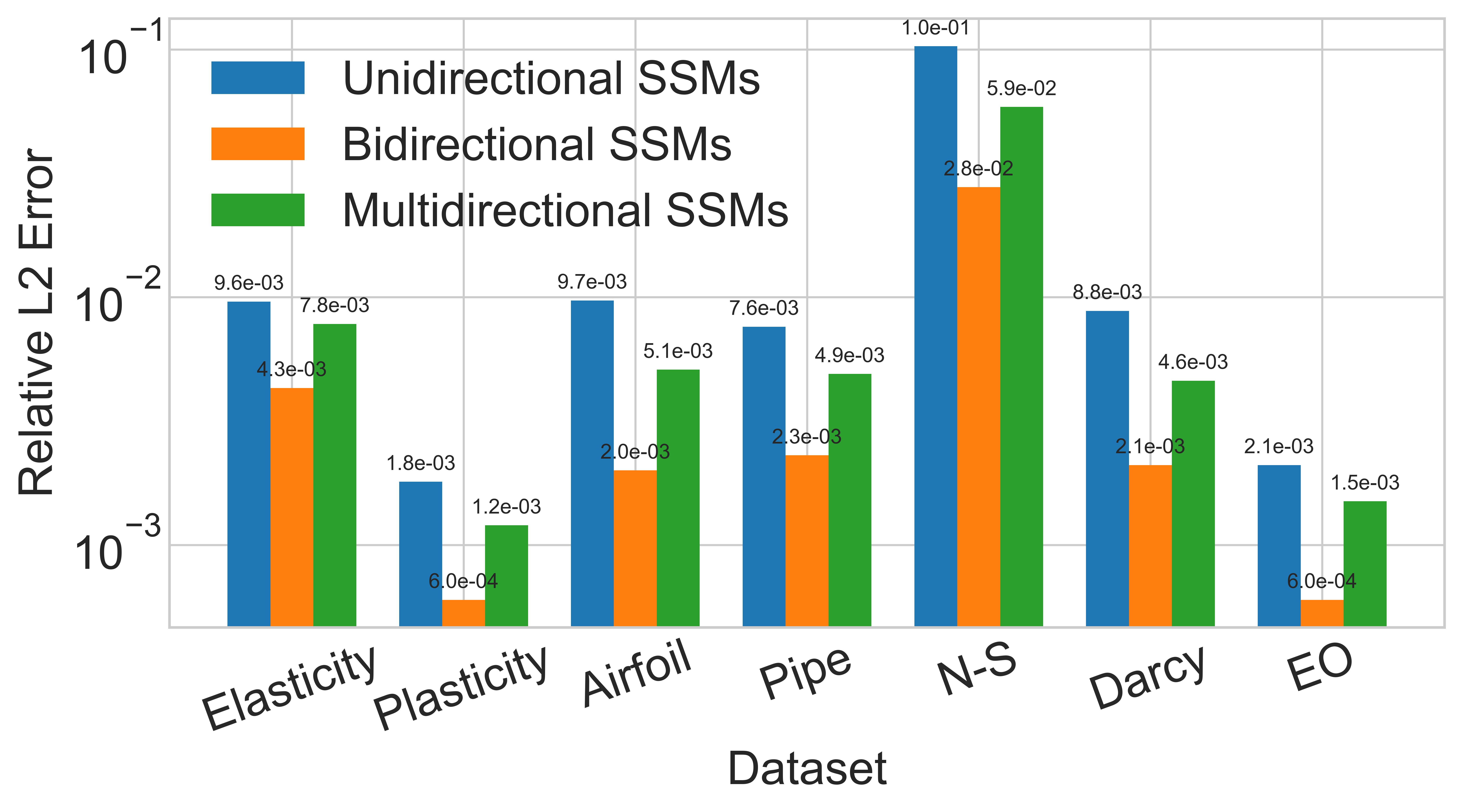

Adaptive Mamba Neural OperatorsZeyuan Song and Zheyu JiangIn The Fourteenth International Conference on Learning Representations, 2026Accurately solving partial differential equations (PDEs) on arbitrary geometries and a variety of meshes is an important task in science and engineering applications. In this paper, we propose Adaptive Fourier Mamba Operators (AFMO), which integrates reproducing kernels for state-space models (SSMs) rather than the kernel integral formulation of SSMs. This is achieved by constructing Takenaka-Malmquist systems for the PDEs. AFMO offers new representations that align well with the adaptive Fourier decomposition (AFD) theory and can approximate the solution manifold of PDEs on a wide range of geometries and meshes. In several challenging benchmark PDE problems in the field of fluid physics, solid physics, and finance on point clouds, structured meshes, regular grids, and irregular domains, AFMO consistently outperforms state-of-the-art solvers in terms of relative L^2 error. Overall, this work presents a new paradigm for designing explainable neural operator frameworks.

@inproceedings{iclr2026, title = {Adaptive Mamba Neural Operators}, author = {Song, Zeyuan and Jiang, Zheyu}, year = {2026}, booktitle = {The Fourteenth International Conference on Learning Representations}, url = {https://openreview.net/forum?id=OenyzvFZPs}, } - ICASSP 2026

On Optimization of Poles for Adaptive Fourier Decomposition-inspired Neural LayersZeyuan Song and Zheyu JiangIn 2026 IEEE International Conference on Acoustics, Speech, and Signal Processing, 2026

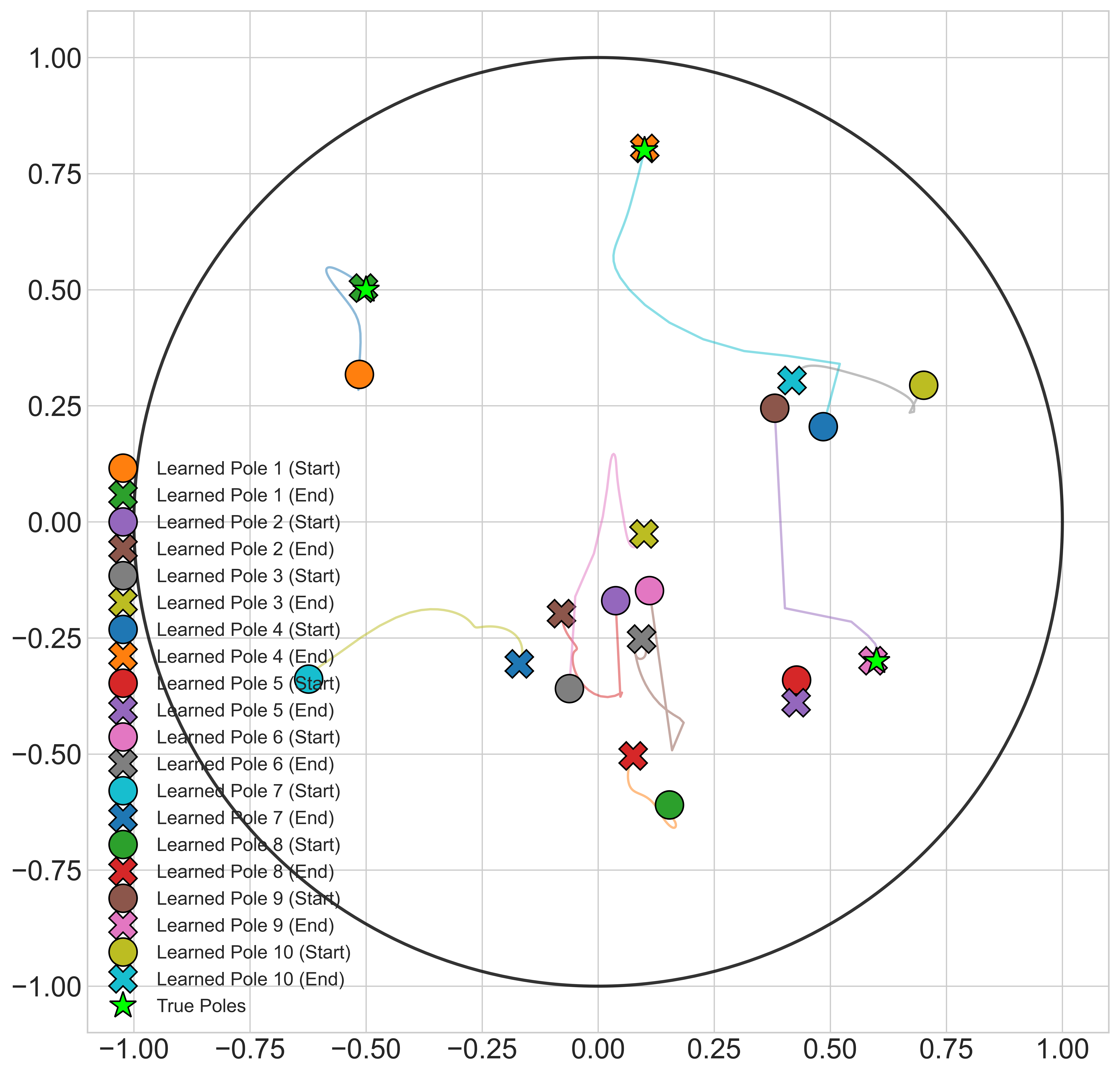

On Optimization of Poles for Adaptive Fourier Decomposition-inspired Neural LayersZeyuan Song and Zheyu JiangIn 2026 IEEE International Conference on Acoustics, Speech, and Signal Processing, 2026Spectral methods and their variants are important numerical approaches for solving PDE problems. However, the performance of these methods deteriorates when solutions contain singularities or sharp gradients. In this work, we integrate Adaptive Fourier Decomposition (AFD) with Blaschke-type bases into a neural operator architecture for solving forward and inverse PDEs. A central challenge in AFD-inspired neural operator is how to select AFD poles, which lie on the unit disk (a Riemannian manifold), and network hyperparameters, which lie in Euclidean space. We address this in an optimization framework, which alternates between Riemannian gradient steps for pole updates and Euclidean steps for network parameters. We prove descent and linear convergence to first-order critical points under standard strong-convexity and cross-block coupling conditions. A greedy outer loop adaptively increases the number of poles and is provably convergent, attaining the global optimum when the target is exactly representable. Experiments on Burgers’ (forward problem) and Darcy flow (inverse problem) equations demonstrate improved accuracy and efficiency over Euclidean-only variants and competitive baseline methods, illustrating the need and benefits of manifold-aware pole optimization in AFD-based neural operators.

@inproceedings{icassp2026, title = {On Optimization of Poles for Adaptive Fourier Decomposition-inspired Neural Layers}, author = {Song, Zeyuan and Jiang, Zheyu}, year = {2026}, booktitle = {2026 IEEE International Conference on Acoustics, Speech, and Signal Processing}, }

2025

- C&G

MP-FVM: Enhancing finite volume method for water infiltration modeling in unsaturated soils via message-passing encoder-decoder networkZeyuan Song and Zheyu JiangComputers and Geotechnics, 2025

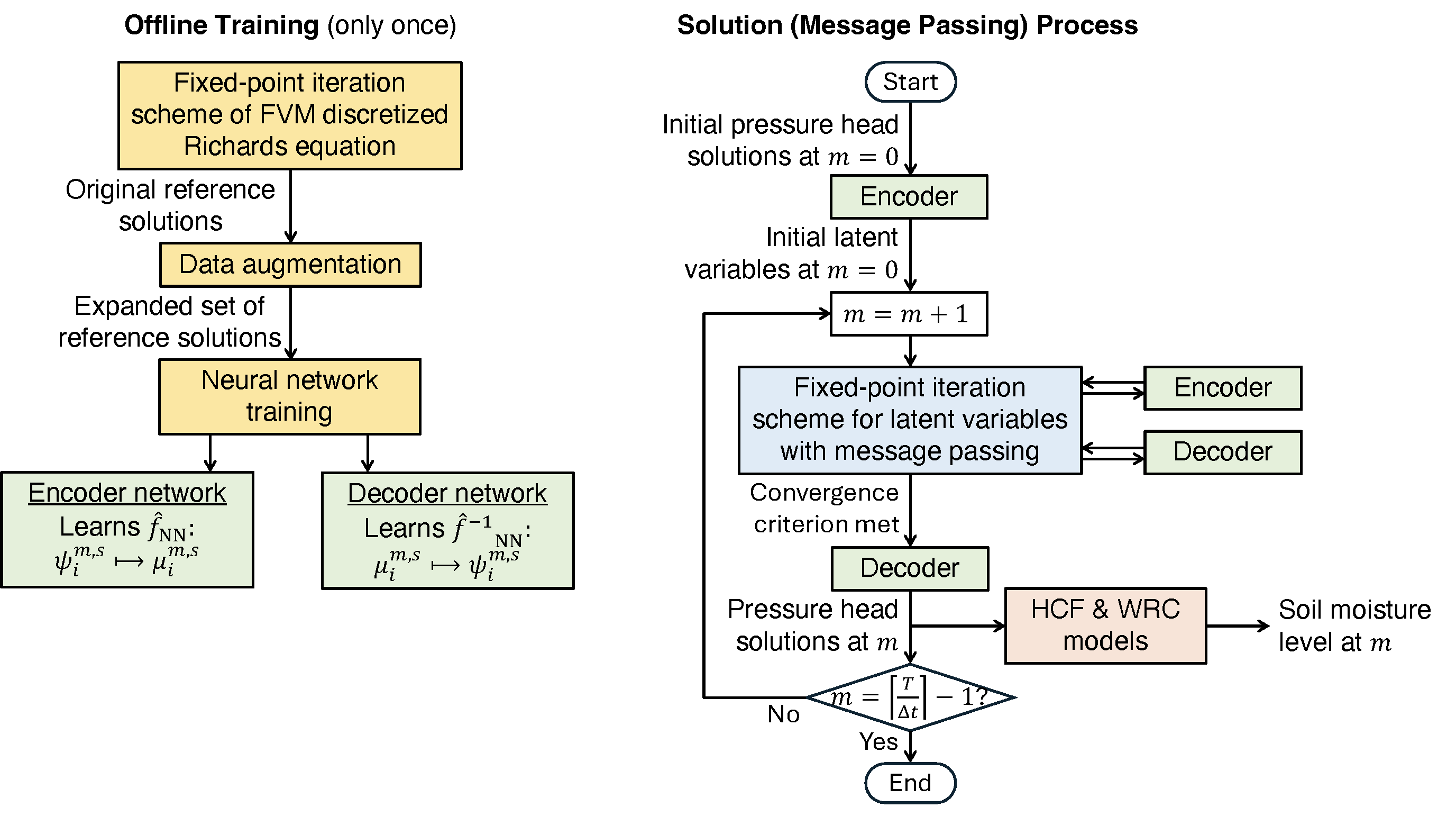

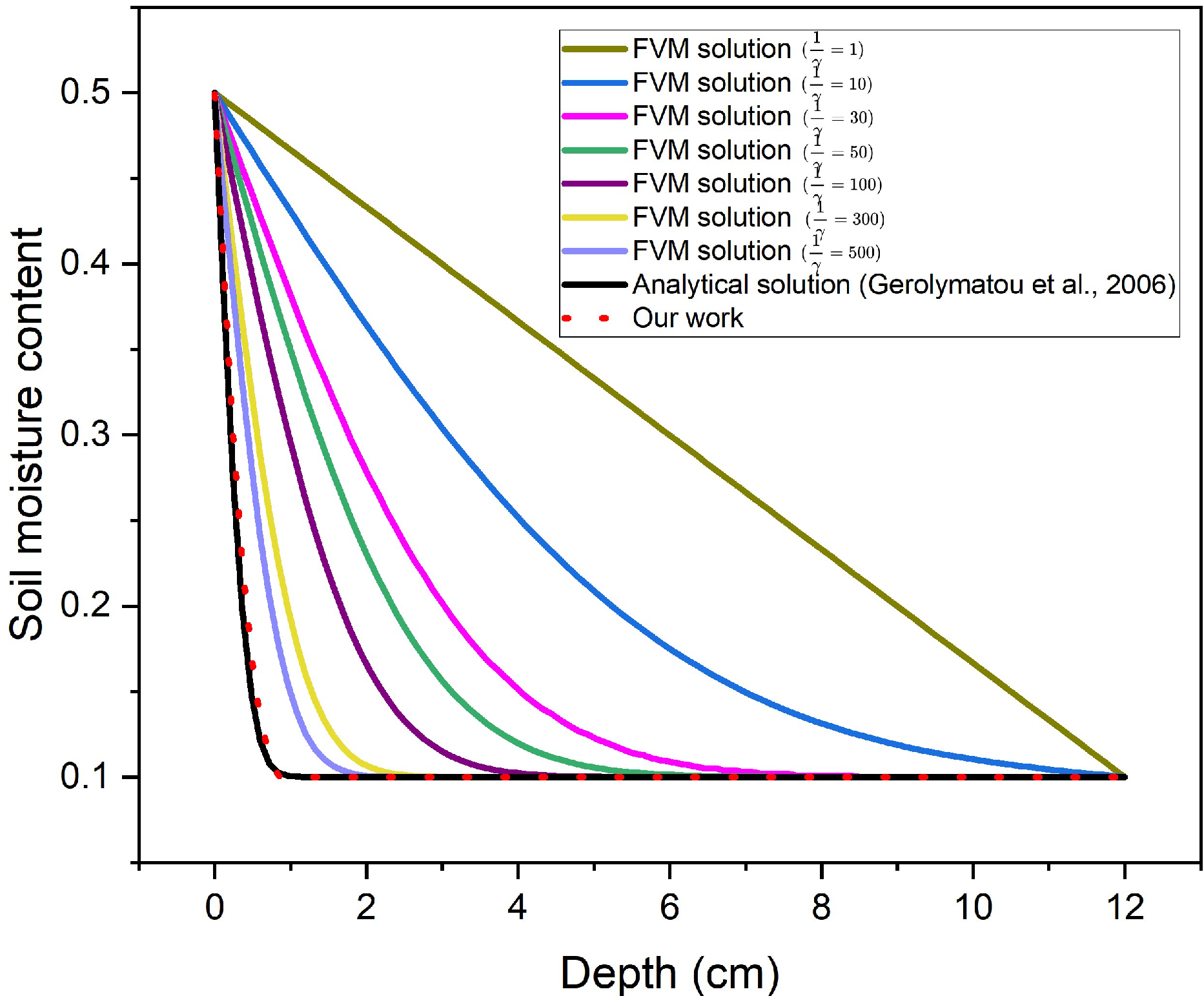

MP-FVM: Enhancing finite volume method for water infiltration modeling in unsaturated soils via message-passing encoder-decoder networkZeyuan Song and Zheyu JiangComputers and Geotechnics, 2025The spatiotemporal water flow dynamics in unsaturated soils can generally be modeled by the Richards equation. To overcome the computational challenges associated with solving this highly nonlinear partial differential equation (PDE), we present a novel solution algorithm, which we name as the MP-FVM (Message Passing-Finite Volume Method), to holistically integrate adaptive fixed-point iteration scheme, encoder-decoder neural network architecture, Sobolev training, and message passing mechanism in a finite volume discretization framework. We thoroughly discuss the need and benefits of introducing these components to achieve synergistic improvements in accuracy and stability of the solution. We also show that our MP-FVM algorithm can accurately solve the mixed-form n-dimensional Richards equation with guaranteed convergence under reasonable assumptions. Through several illustrative examples, we demonstrate that our MP-FVM algorithm not only achieves superior accuracy, but also better preserves the underlying physical laws and mass conservation of the Richards equation compared to state-of-the-art solution algorithms and the commercial HYDRUS solver.

@article{songjiang, title = {MP-FVM: Enhancing finite volume method for water infiltration modeling in unsaturated soils via message-passing encoder-decoder network}, author = {Song, Zeyuan and Jiang, Zheyu}, year = {2025}, journal = {Computers and Geotechnics}, volume = {190}, pages = {107745}, issn = {0266-352X}, doi = {https://doi.org/10.1016/j.compgeo.2025.107745}, url = {https://www.sciencedirect.com/science/article/pii/S0266352X25006949}, } - AIChE

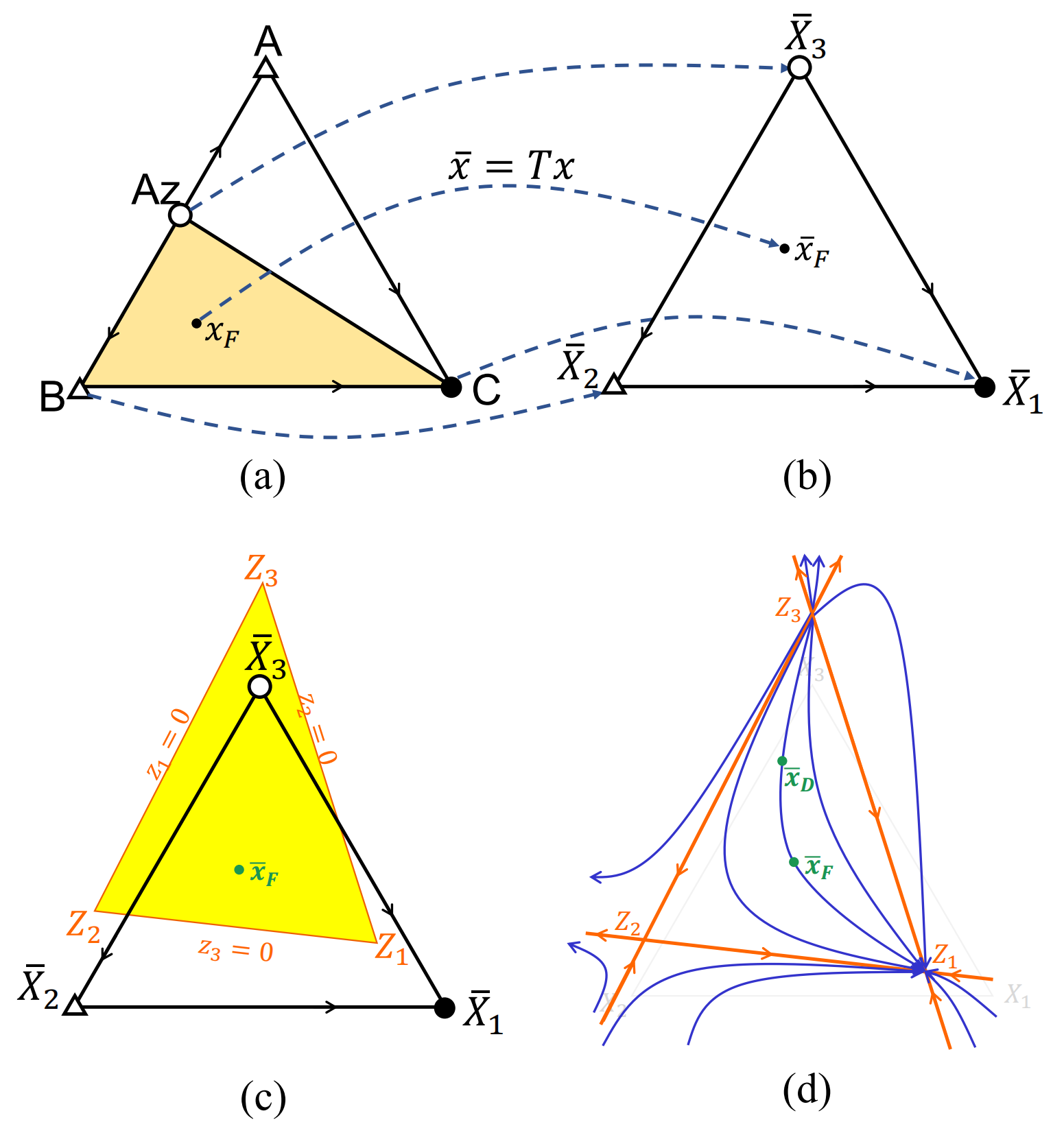

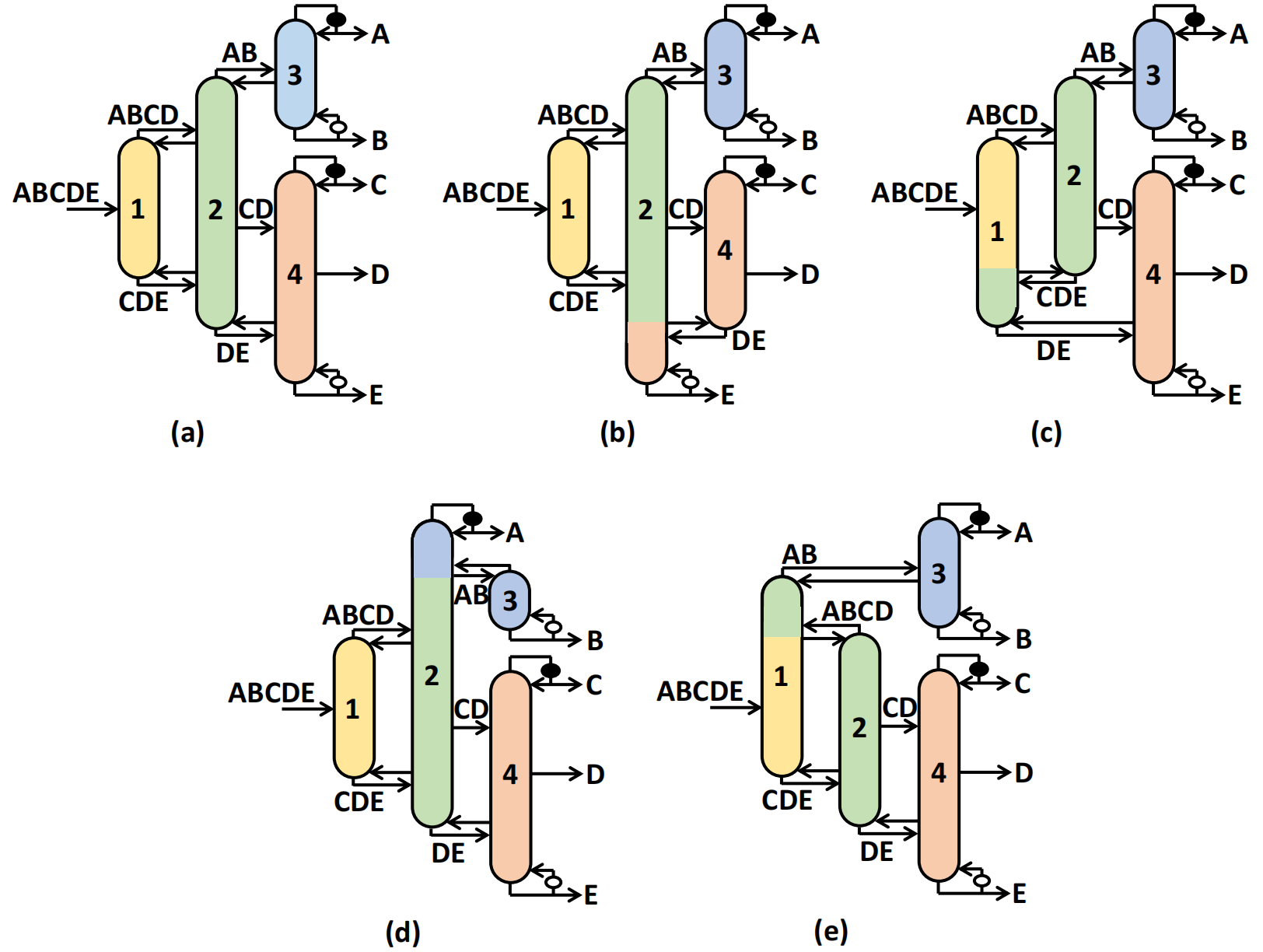

Minimum reflux calculation for multicomponent distillation in multi-feed, multi-product columns: Algorithms and examplesZheyu Jiang, Mohit Tawarmalani, and Rakesh AgrawalAIChE Journal, 2025

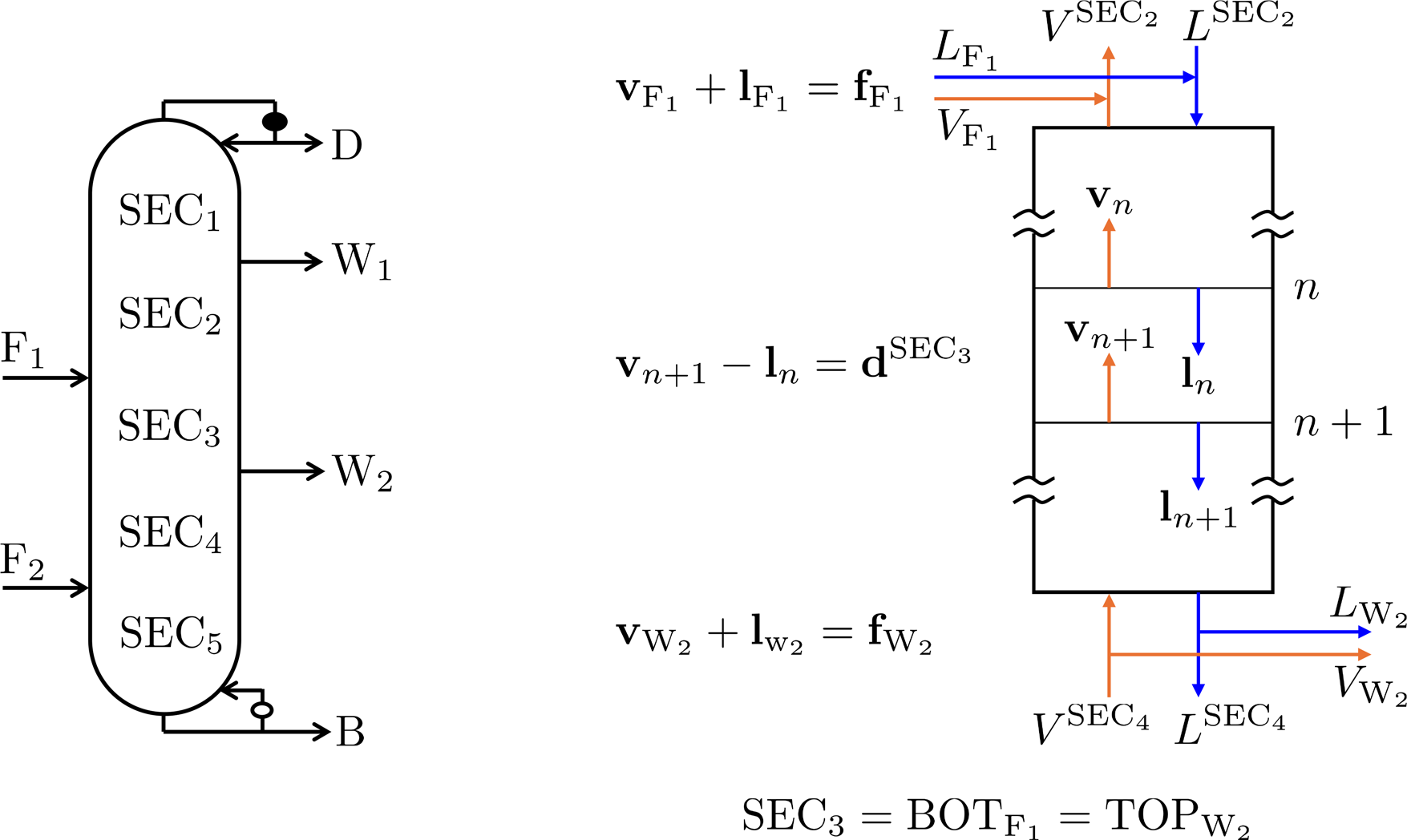

Minimum reflux calculation for multicomponent distillation in multi-feed, multi-product columns: Algorithms and examplesZheyu Jiang, Mohit Tawarmalani, and Rakesh AgrawalAIChE Journal, 2025Abstract In this work, we present the first algorithm for identifying the minimum reboiler vapor duty requirement for a general multi-feed, multi-product (MFMP) distillation column separating ideal multicomponent mixtures. This algorithm incorporates our recently developed shortcut model for MFMP columns. We demonstrate the accuracy and efficiency of this algorithm through case studies. The results obtained from these case studies provide valuable insights into the optimal design of MFMP columns. Many of these insights go against the existing design guidelines and heuristics. For example, placing a colder saturated feed stream above a hotter saturated feed stream sometimes leads to a higher energy requirement. Furthermore, decomposing a general MFMP column into individual simple columns may lead to incorrect estimation of the minimum reflux ratio for the MFMP column. Thus, the algorithm presented here offers a fast, accurate, and automated approach to synthesize new, energy-efficient, and cost-effective MFMP columns.

@article{jiang:2022:mfmp2, author = {Jiang, Zheyu and Tawarmalani, Mohit and Agrawal, Rakesh}, title = {Minimum reflux calculation for multicomponent distillation in multi-feed, multi-product columns: Algorithms and examples}, journal = {AIChE Journal}, year = {2025}, volume = {n/a}, number = {n/a}, pages = {e70016}, keywords = {minimum reflux ratio, multi-feed and multi-product distillation column, Multicomponent distillation, optimization, Underwood method}, } - IECR

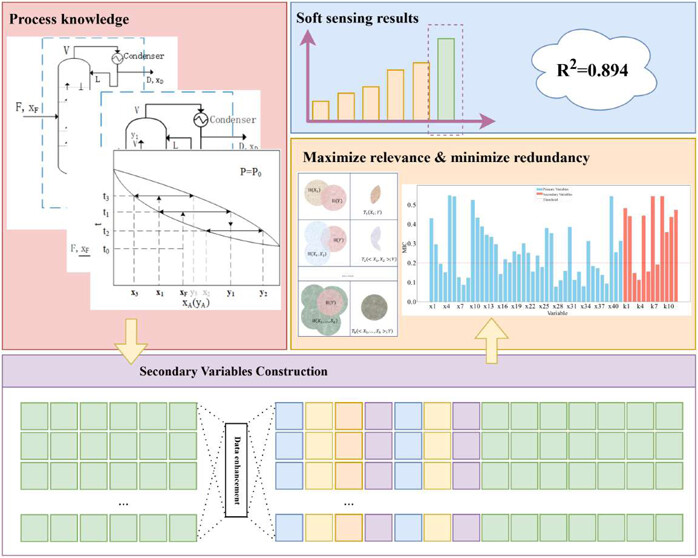

Harnessing Process Knowledge via Soft Sensing for Accurate Online Monitoring: A Study on the Dow Data Challenge ProblemWantong Fang, Cheng Ji, Fangyuan Ma, and 3 more authorsIndustrial & Engineering Chemistry Research, 2025

Harnessing Process Knowledge via Soft Sensing for Accurate Online Monitoring: A Study on the Dow Data Challenge ProblemWantong Fang, Cheng Ji, Fangyuan Ma, and 3 more authorsIndustrial & Engineering Chemistry Research, 2025Process monitoring is a critical component in modern manufacturing facilities to guarantee process safety, ensure product quality, and improve process operability. In this work, we present a lightweight yet effective process monitoring framework that synergistically incorporates useful process knowledge into online monitoring. This new framework can greatly enhance the monitoring capabilities of existing sensing infrastructure without installing new physical sensors. The idea is to smartly construct essential secondary variables based on domain knowledge to uncover underlying process behaviors, followed by carefully selecting process variables with minimal redundancy for soft sensing. Both secondary variable construction and variable selection approaches are part of data preprocessing steps and thus can be easily done offline and integrated with a range of soft sensing algorithms. Compared to existing soft sensor modeling approaches that rely on complex deep learning architectures, our framework does not require extensive training and can be generalized to other monitoring applications. We also introduce and incorporate an adaptive variable selection mechanism based on the concept of mutual information to select original and secondary variables for monitoring, which significantly reduces measurement redundancy and further improves computational efficiency and monitoring accuracy. Together, these innovations lead to the highest accuracy (R2 = 0.894) ever reported in the literature in online estimation of product impurity concentration in the Dow data challenge problem. Overall, our proposed monitoring framework offers a scalable, lightweight, and explainable solution for real-time process monitoring and quality control of manufacturing processes.

@article{fang:2025:softsensing, author = {Fang, Wantong and Ji, Cheng and Ma, Fangyuan and Jiang, Zheyu and Wang, Jingde and Sun, Wei}, title = {Harnessing Process Knowledge via Soft Sensing for Accurate Online Monitoring: A Study on the Dow Data Challenge Problem}, journal = {Industrial \& Engineering Chemistry Research}, volume = {64}, number = {31}, pages = {15363-15376}, year = {2025}, doi = {10.1021/acs.iecr.5c01644}, url = {https://doi.org/10.1021/acs.iecr.5c01644}, eprint = {https://doi.org/10.1021/acs.iecr.5c01644}, } - CACE

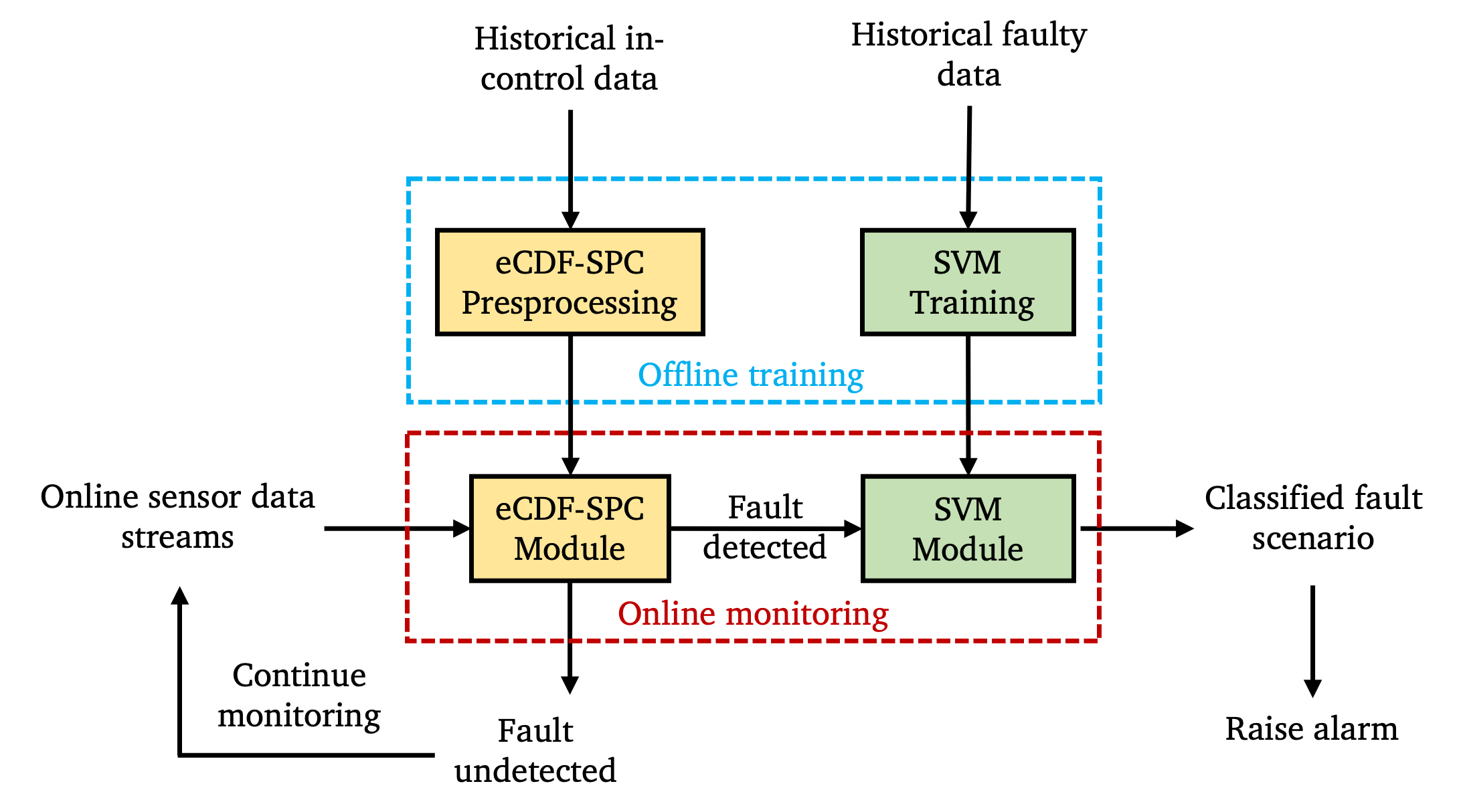

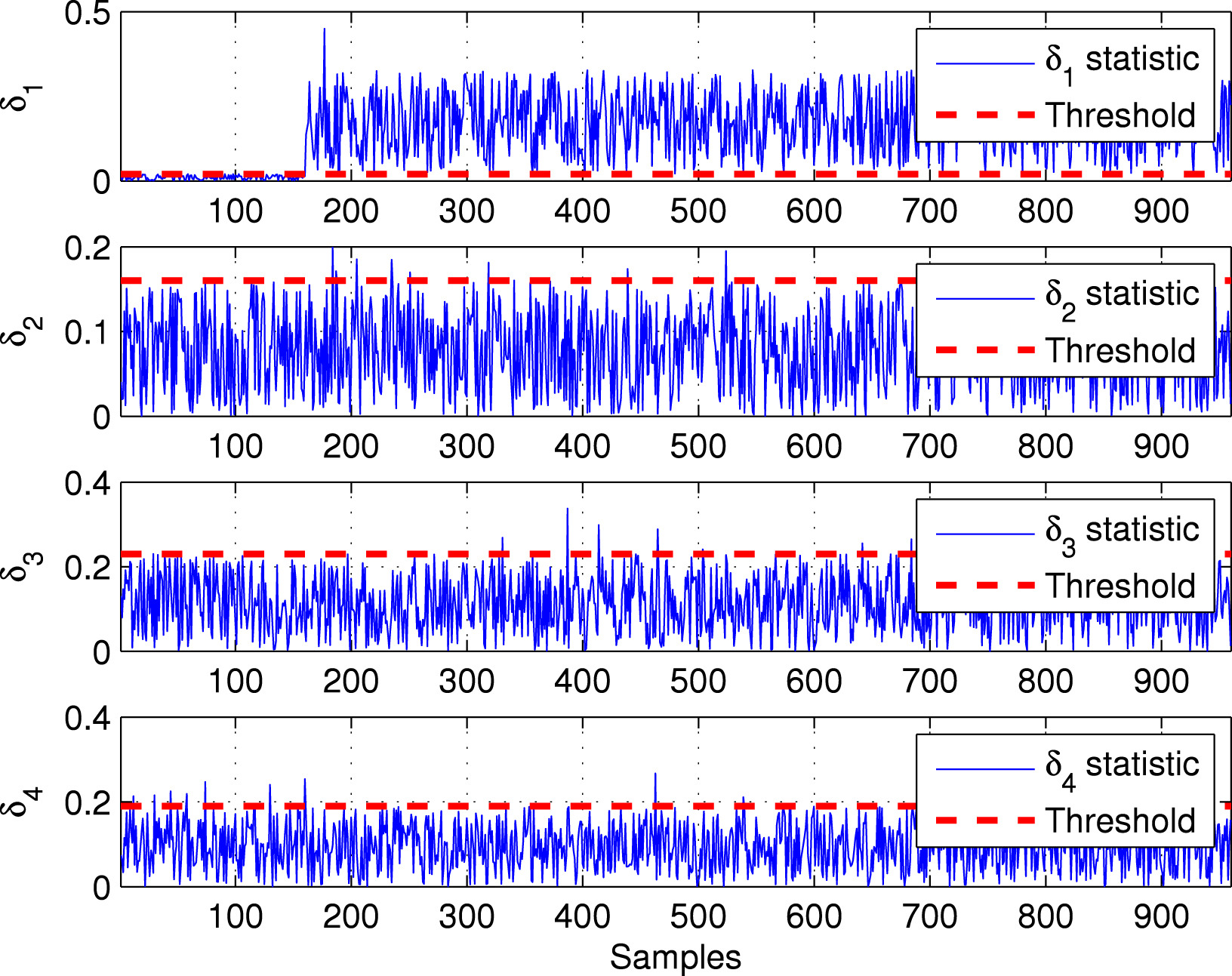

Online fault detection and classification of chemical process systems leveraging statistical process control and Riemannian geometric analysisAlireza Miraliakbar, Fangyuan Ma, and Zheyu JiangComputers & Chemical Engineering, 2025

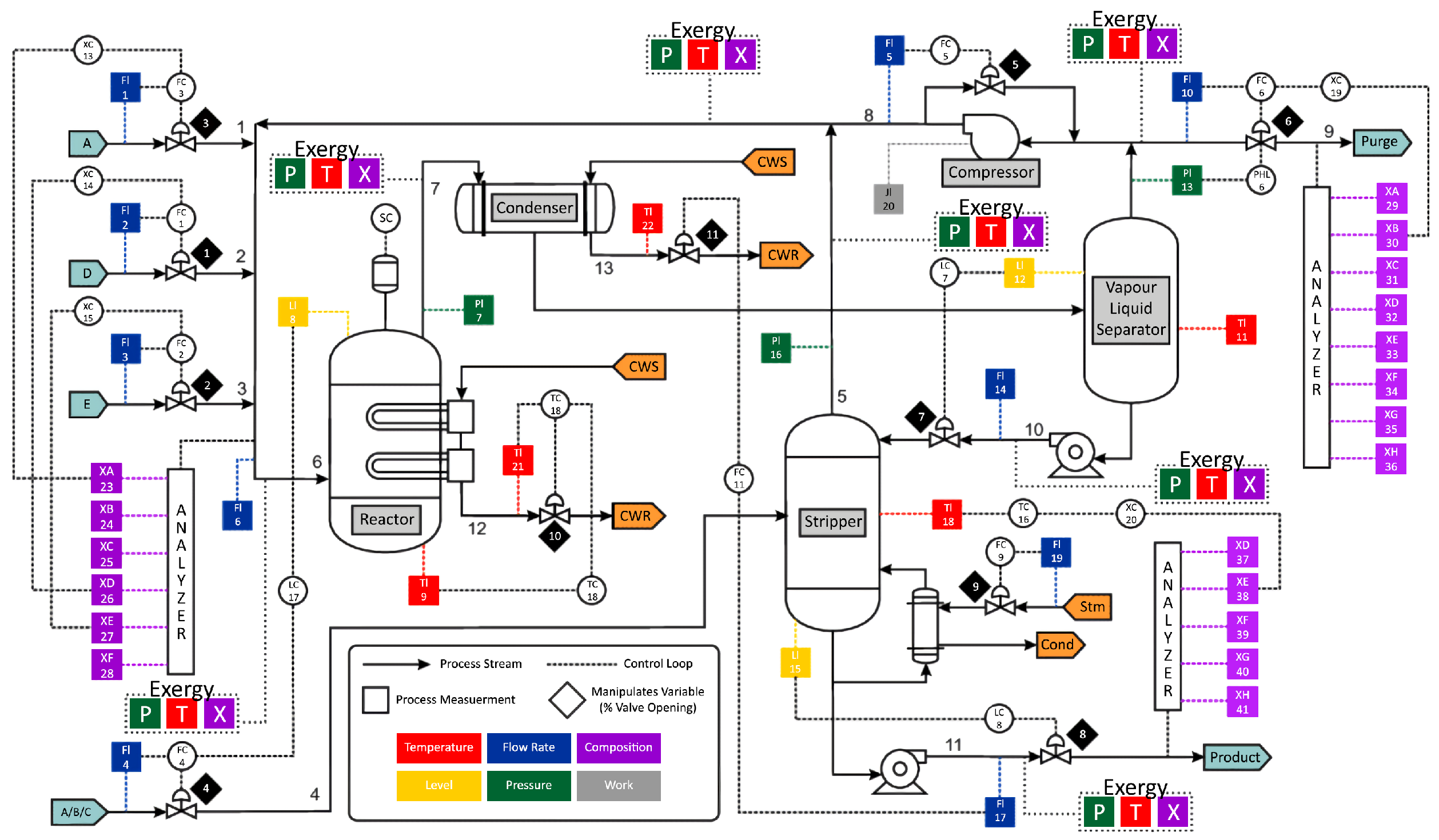

Online fault detection and classification of chemical process systems leveraging statistical process control and Riemannian geometric analysisAlireza Miraliakbar, Fangyuan Ma, and Zheyu JiangComputers & Chemical Engineering, 2025In this work, we study an integrated fault detection and classification framework called FARM for fast, accurate, and robust online chemical process monitoring. The FARM framework integrates the latest advancements in statistical process control (SPC) for monitoring nonparametric and heterogeneous data streams with novel data analysis approaches based on Riemannian geometry together in a hierarchical framework for online process monitoring. We conduct a systematic evaluation of the FARM monitoring framework using the Tennessee Eastman Process (TEP) dataset. Results show that FARM performs competitively against state-of-the-art process monitoring algorithms by achieving a good balance among fault detection rate (FDR), fault detection speed (FDS), and false alarm rate (FAR). Specifically, FARM achieved an average FDR of 96.16% while also outperforming benchmark methods in successfully detecting hard-to-detect faults that are previously known, including Faults 3, 9 and 15, with FDRs being 96.03%, 94.83% and 94.20%, respectively. In terms of FAR, our FARM framework allows practitioners to customize their choice of FAR, thereby offering great flexibility. Moreover, we report a significant improvement in average fault classification accuracy during online monitoring from 61% to 82% when leveraging Riemannian geometric analysis, and further to 84.5% when incorporating additional features from SPC. This illustrates the synergistic effect of integrating fault detection and classification in a holistic, hierarchical monitoring framework.

@article{miraliakbar:2025:online, title = {Online fault detection and classification of chemical process systems leveraging statistical process control and Riemannian geometric analysis}, journal = {Computers & Chemical Engineering}, volume = {200}, pages = {109177}, year = {2025}, issn = {0098-1354}, doi = {https://doi.org/10.1016/j.compchemeng.2025.109177}, url = {https://www.sciencedirect.com/science/article/pii/S0098135425001814}, author = {Miraliakbar, Alireza and Ma, Fangyuan and Jiang, Zheyu}, keywords = {Process monitoring, Fault detection, Fault classification, Riemannian geometry, Statistical process control}, } - ESCAPE35

A Novel Bayesian Framework for Inverse Problems in Precision AgricultureZeyuan Song and Zheyu JiangIn Systems and Control Transactions, Jul 2025

A Novel Bayesian Framework for Inverse Problems in Precision AgricultureZeyuan Song and Zheyu JiangIn Systems and Control Transactions, Jul 2025An essential problem in precision agriculture is to accurately model and predict root-zone (top 1 m of soil) soil moisture profile given soil properties and precipitation and evapotranspiration information. This is typically achieved by solving agro-hydrological models. Nowadays, most of these models are based on the standard Richards equation (RE), a highly nonlinear, degenerate elliptic-parabolic partial differential equation that describes irrigation, precipitation, evapotranspiration, runoff, and drainage through soils. Recently, the standard RE has been generalized to time-fractional RE with any fractional order between 0 and 2. Such generalization allows the characterization of anomalous soil exhibiting non-Boltzmann behavior due to the presence of preferential flow. In this work, we focus on inverse modeling of time-fractional RE; that is, how to accurately estimate the fractional order and soil property parameters of the fractional RE given soil moisture content measurements. Specifically, we introduce a novel Bayesian variational autoencoder (BVAE) framework that synergistically integrates our in-house developed fractional RE solver and adaptive Fourier decomposition (AFD) to accurately estimate the parameters of time-fractional RE. Our proposed AFD-enhanced BVAE framework consists of a probabilistic encoder, latent-to-kernel neural networks and convolutional neural networks. The BVAE framework is theoretically explainable and enhanced by the AFD theory, a novel signal processing technique that achieves superior computationally efficiency. Through illustrative examples, we demonstrate the efficiency and reliability of our AFD-enhanced BVAE framework.

@inproceedings{song:2025:inverse, author = {Song, Zeyuan and Jiang, Zheyu}, year = {2025}, month = jul, pages = {246-251}, title = {A Novel Bayesian Framework for Inverse Problems in Precision Agriculture}, doi = {10.69997/sct.113662}, booktitle = {Systems and Control Transactions} } - ESCAPE35

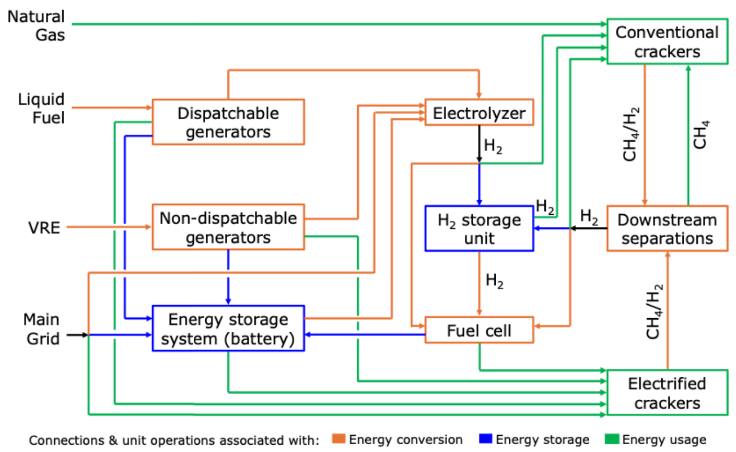

Multi-objective Optimization of Steam Cracking Microgrid for Clean Olefins ProductionSaba Naraghi, Tylee Kareck, and Zheyu JiangIn Systems and Control Transactions, Jul 2025

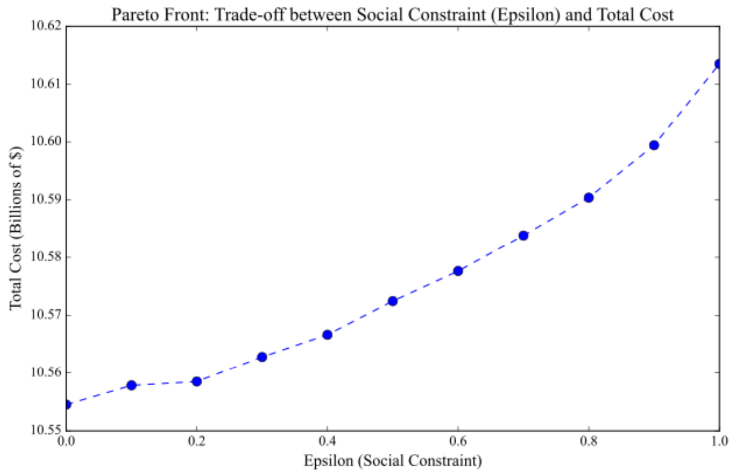

Multi-objective Optimization of Steam Cracking Microgrid for Clean Olefins ProductionSaba Naraghi, Tylee Kareck, and Zheyu JiangIn Systems and Control Transactions, Jul 2025Olefins are essential precursors in producing a wide range of chemical products, including plastics, detergents, adhesives, rubber, and food packaging. Ethylene and propylene are the most ubiquitous olefin components and are predominantly produced through steam cracking. However, steam cracking is highly energy- and carbon-intensive, making its decarbonization a priority as the energy sector shifts toward clean, renewable electricity. Electrifying the steam cracking process is a promising pathway to reduce carbon emissions. However, this is challenged by the intrinsic conflict between the continuous operational nature of ethylene plants and the intermittent nature of renewable energy sources (e.g., solar and wind) in modern power systems. Massive energy storage systems or full plant reconfigurations to meet the power demand of electrified crackers are shown to be economically and practically infeasible. Thus, a more viable solution is to pursue a gradual electrification pathway and operate an ethylene plant as a microgrid that adopts diverse energy sources. To optimize the operational strategy of such a microgrid considering uncertainties in renewable energy generation and market prices, in this work, we introduce a stochastic multi-objective optimization approach that minimizes operating costs and carbon emissions of steam cracking. Results from a case study not only elucidate the trade-offs between economic and environmental objectives, but also provide insights into the optimal operating scheme in sustainable ethylene production.

@inproceedings{saba:2025:microgrid, author = {Naraghi, Saba and Kareck, Tylee and Jiang, Zheyu}, year = {2025}, month = jul, pages = {837-843}, title = {Multi-objective Optimization of Steam Cracking Microgrid for Clean Olefins Production}, doi = {10.69997/sct.185984}, booktitle = {Systems and Control Transactions} } - ESCAPE35

Joint Optimization of Fair Facility Allocation and Robust Inventory Management for Perishable Consumer ProductsSaba Naraghi and Zheyu JiangIn Systems and Control Transactions, Jul 2025

Joint Optimization of Fair Facility Allocation and Robust Inventory Management for Perishable Consumer ProductsSaba Naraghi and Zheyu JiangIn Systems and Control Transactions, Jul 2025Perishable consumer products like food, cosmetics, and household chemicals face challenges in supply chain management due to limited shelf life and uncertainties in demand and transportation. To address some of these issues, this work proposes a robust optimization framework for jointly optimizing facility allocation and inventory management. The framework determines optimal locations for distribution centers and their assigned customers, as well as inventory policies that minimize the total costs related to transportation, distribution, and storage under uncertain demand in a robust setting. Specifically, we develop a two-stage mixed-integer linear programming (MILP) model is that incorporates First-In-First-Out (FIFO) inventory policy to reduce spoilage. The bilinear FIFO constraints are linearized to improve computational efficiency. Social equity is integrated by defining a fairness index and incorporating it in facility allocation. Demand uncertainty is tackled using a robust optimization approach with affine demand functions to handle multiple scenarios. The model is solved using row and column generation techniques for scalability. Overall, this robust optimization framework is expected to enhance supply chain resilience, reduce waste, and improve cost-effectiveness in managing perishable products.

@inproceedings{saba:2025:supplychain, author = {Naraghi, Saba and Jiang, Zheyu}, year = {2025}, month = jul, pages = {882-887}, title = {Joint Optimization of Fair Facility Allocation and Robust Inventory Management for Perishable Consumer Products}, doi = {10.69997/sct.153925}, booktitle = {Systems and Control Transactions} } - ESCAPE35

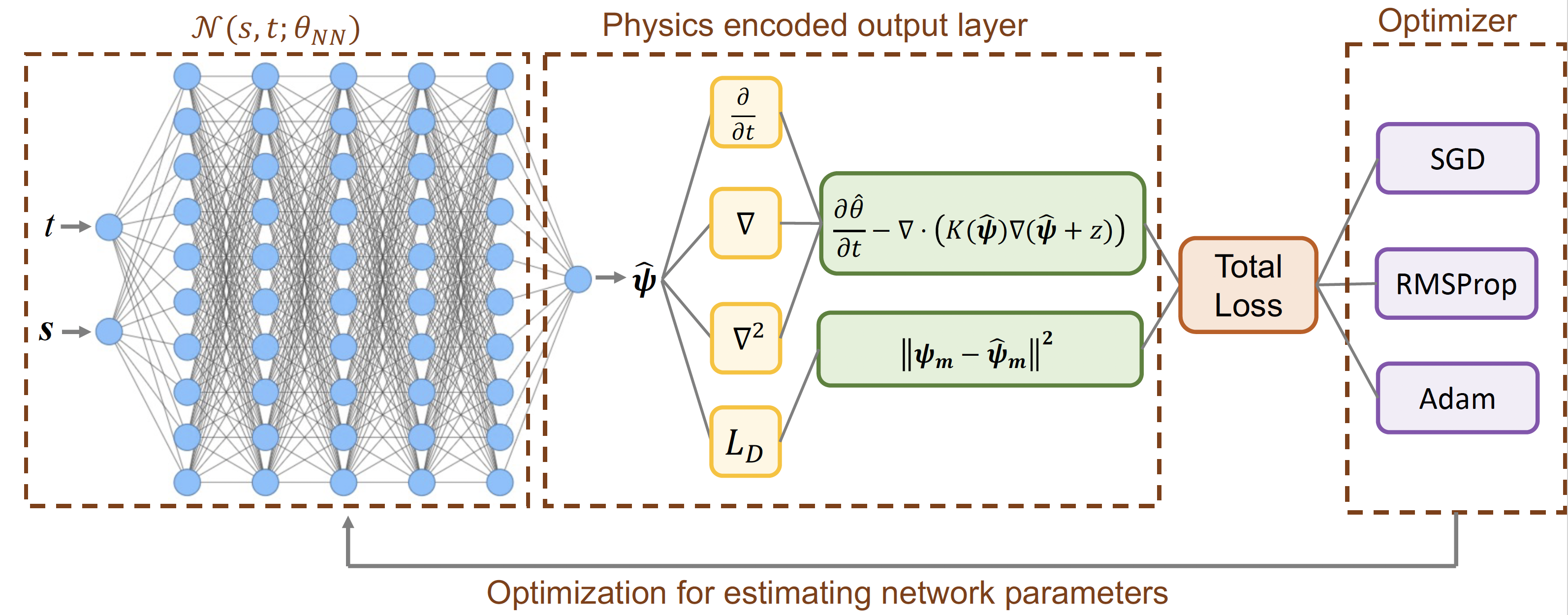

A Physics-based, Data-driven Numerical Framework for Anomalous Diffusion of Water in SoilZeyuan Song and Zheyu JiangIn Systems and Control Transactions, Jul 2025

A Physics-based, Data-driven Numerical Framework for Anomalous Diffusion of Water in SoilZeyuan Song and Zheyu JiangIn Systems and Control Transactions, Jul 2025Precision modeling and forecasting of soil moisture are essential for implementing smart irrigation systems and mitigating agricultural drought. Most agro-hydrological models are based on the standard Richards equation, a highly nonlinear, degenerate elliptic-parabolic partial differential equation (PDE) with first order time derivative. However, research has shown that standard Richards equation is unable to model preferential flow in soil with fractal structure. In such a scenario, the soil exhibits anomalous non-Boltzmann scaling behavior. Incorporating the anomalous non-Boltzmann scaling behavior into the Richards equation leads to a generalized, time-fractional Richards equation based on fractional time derivatives. As expected, solving the time-fractional Richards equation for accurate modeling of water flow dynamics in soil faces extensive computational challenges. To target these challenges, we propose a novel numerical method that integrates finite volume method (FVM), adaptive fixed point iteration scheme, and neural network to solve the time-fractional Richards equation. Specifically, we develop an adaptive fixed point iteration scheme to solve the FVM-discretized equation iteratively, which avoids the stability issues when directly solving a stiff and sparse matrix equation. To improve the solution quality which is influenced by numerical errors and computational constraints during actual implementation, we propose to use neural networks that resemble an encoder-decoder architecture to map soil moisture profiles into a latent space and reconstruct them back. Through 1-D examples, we illustrate the accuracy and computational efficiency of our proposed physics-based, data-driven numerical method. Finally, we present a Markov chain Monte Carlo (MCMC) approach to solve the inverse problem to obtain soil-specific parameters given soil moisture solutions.

@inproceedings{song:2025:fractional, author = {Song, Zeyuan and Jiang, Zheyu}, year = {2025}, month = jul, pages = {2391-2397}, title = {A Physics-based, Data-driven Numerical Framework for Anomalous Diffusion of Water in Soil}, doi = {10.69997/sct.163304}, booktitle = {Systems and Control Transactions} }

2024

- Processes

MOLA: Enhancing Industrial Process Monitoring Using a Multi-Block Orthogonal Long Short-Term Memory AutoencoderFangyuan Ma, Cheng Ji, Jingde Wang, and 3 more authorsProcesses, Dec 2024

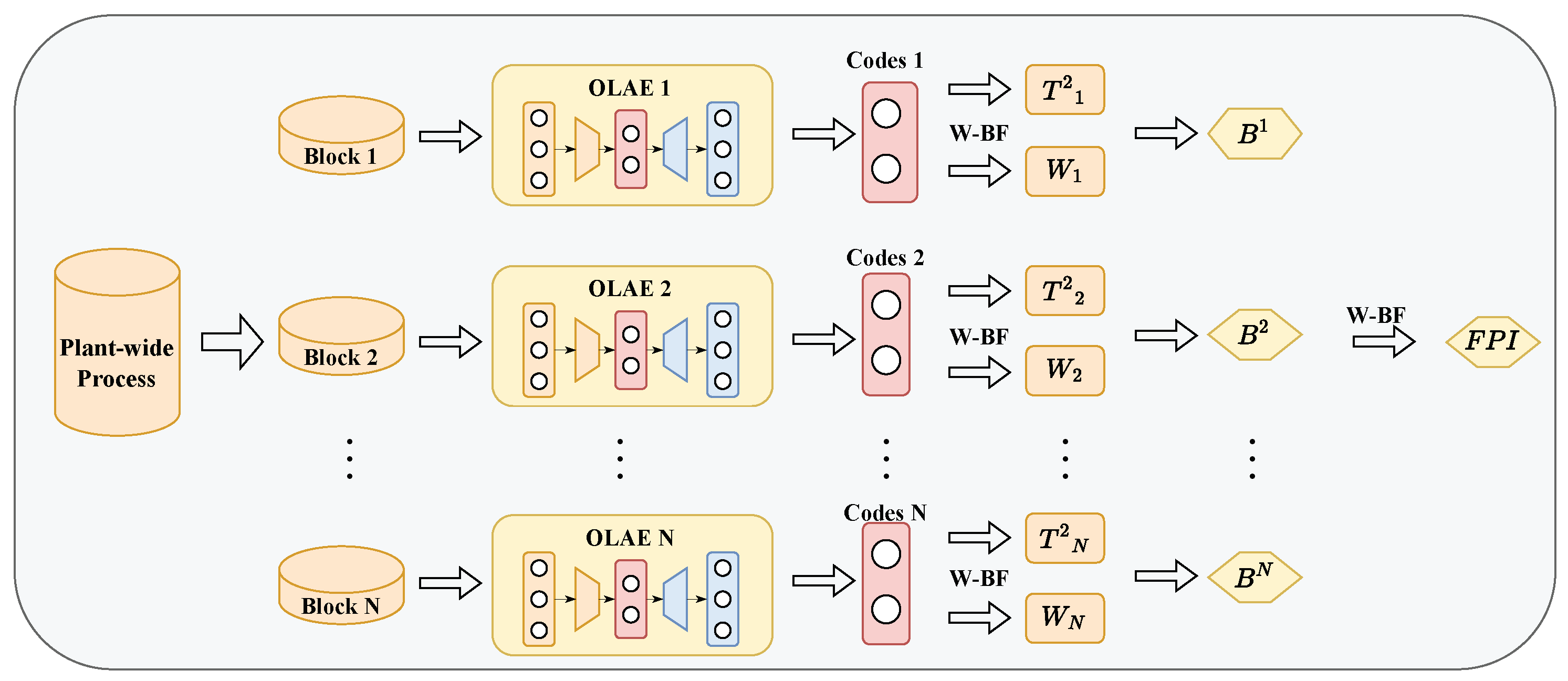

MOLA: Enhancing Industrial Process Monitoring Using a Multi-Block Orthogonal Long Short-Term Memory AutoencoderFangyuan Ma, Cheng Ji, Jingde Wang, and 3 more authorsProcesses, Dec 2024In this work, we introduce MOLA, a multi-block orthogonal long short-term memory autoencoder paradigm, to conduct accurate, reliable fault detection of industrial processes. To achieve this, MOLA effectively extracts dynamic orthogonal features by introducing an orthogonality-based loss function to constrain the latent space output. This helps eliminate the redundancy in the features identified, thereby improving the overall monitoring performance. On top of this, a multi-block monitoring structure is proposed, which categorizes the process variables into multiple blocks by leveraging expert process knowledge about their associations with the overall process. Each block is associated with its specific orthogonal long short-term memory autoencoder model, whose extracted dynamic orthogonal features are monitored by distance-based Hotelling’s T2 statistics and quantile-based cumulative sum (CUSUM) designed for multivariate data streams that are nonparametric and heterogeneous. Compared to having a single model accounting for all process variables, such a multi-block structure significantly improves overall process monitoring performance, especially for large-scale industrial processes. Finally, we propose an adaptive weight-based Bayesian fusion (W-BF) framework to aggregate all block-wise monitoring statistics into a global statistic that we monitor for faults. Fault detection speed and accuracy are improved by assigning and adjusting weights to blocks based on the sequential order in which alarms are raised. We demonstrate the efficiency and effectiveness of our MOLA framework by applying it to the Tennessee Eastman process and comparing the performance with various benchmark methods.

@article{fangyuan:2024:mola, author = {Ma, Fangyuan and Ji, Cheng and Wang, Jingde and Sun, Wei and Tang, Xun and Jiang, Zheyu}, title = {MOLA: Enhancing Industrial Process Monitoring Using a Multi-Block Orthogonal Long Short-Term Memory Autoencoder}, doi = {https://doi.org/10.3390/pr12122824}, journal = {Processes}, volume = {12}, month = dec, year = {2024}, number = {12}, pages = {2824}, } - FOCAPD 2024

Fast, Accurate, and Robust Fault Detection and Diagnosis of Industrial ProcessesAlireza Miraliakbar and Zheyu JiangSystems and Control Transactions, Jul 2024

Fast, Accurate, and Robust Fault Detection and Diagnosis of Industrial ProcessesAlireza Miraliakbar and Zheyu JiangSystems and Control Transactions, Jul 2024Modern industrial processes are continuously monitored by a large number of sensors. Despite having access to large volumes of historical and online sensor data, industrial practitioners still face challenges in the era of Industry 4.0 in effectively utilizing them to perform online process monitoring and fast fault detection and diagnosis. To target these challenges, in this work, we present a novel framework named “FARM” for Fast, Accurate, and Robust online process Monitoring. FARM is a holistic monitoring framework that integrates (a) advanced multivariate statistical process control (SPC) for fast anomaly detection of nonparametric, heterogeneous data streams, and (b) modified support vector machine (SVM) for accurate and robust fault classification. Unlike existing general-purpose process monitoring frameworks, FARM’s unique hierarchical architecture decomposes process monitoring into two fault detection and diagnosis, each of which is conducted by targeted algorithms. Here, we test and validate the performance of our FARM monitoring framework on Tennessee Eastman Process (TEP) benchmark dataset. We show that SPC achieves faster fault detection speed at a lower false alarm rate compared to state-of-the-art benchmark fault detection methods. In terms of fault classification diagnosis, we show that our modified SVM algorithm successfully classifies 17 out of 20 of the fault scenarios present in the TEP dataset. Compared with the results of standard SVM trained directly on the original dataset, our modified SVM improves the fault classification accuracy significantly.

@article{alireza:2024:focapd, author = {Miraliakbar, Alireza and Jiang, Zheyu}, title = {Fast, Accurate, and Robust Fault Detection and Diagnosis of Industrial Processes}, doi = {https://doi.org/10.69997/sct.108451}, journal = {Systems and Control Transactions}, volume = {3}, year = {2024}, month = jul, pages = {322-329}, }

2023

- ESCAPE33

Online monitoring and robust, reliable fault detection of chemical process systemsZheyu JiangComputer Aided Chemical Engineering, Jun 2023

Online monitoring and robust, reliable fault detection of chemical process systemsZheyu JiangComputer Aided Chemical Engineering, Jun 2023Nowadays, large amounts of data are continuously collected by sensors and monitored in chemical plants. Despite having access to large volumes of historical and online sensor data, industrial practitioners still face several challenges in effectively utilizing them to perform process monitoring and fault detection, because: 1) fault scenarios in chemical processes are naturally complex and cannot be exhaustively enumerated or predicted, 2) sensor measurements continuously produce massive arrays of high-dimensional big data streams that are often nonparametric and heterogeneous, and 3) the strict environmental, health, and safety requirements established in the facilities demand uncompromisingly high reliability and accuracy of any process monitoring and fault detection tool. To address these challenges, in this paper, we introduce a robust and reliable chemical process monitoring framework based on statistical process control (SPC) that can monitor nonparametric and heterogeneous high-dimensional data streams and detect process anomalies as early as possible while maintaining a pre-specified in-control average run length. Through an illustrative case study of the classical Tennessee Eastman Process, we demonstrate the effectiveness of this novel chemical process monitoring framework.

@article{jiang:2023:escape, title = {Online monitoring and robust, reliable fault detection of chemical process systems}, journal = {Computer Aided Chemical Engineering}, volume = {52}, pages = {1621-1626}, year = {2023}, month = jun, doi = {http://dx.doi.org/10.1016/B978-0-443-15274-0.50258-4}, author = {Jiang, Zheyu}, keywords = {Process monitoring, fault detection, statistical process control, CUSUM, big data streams}, } - ESCAPE33

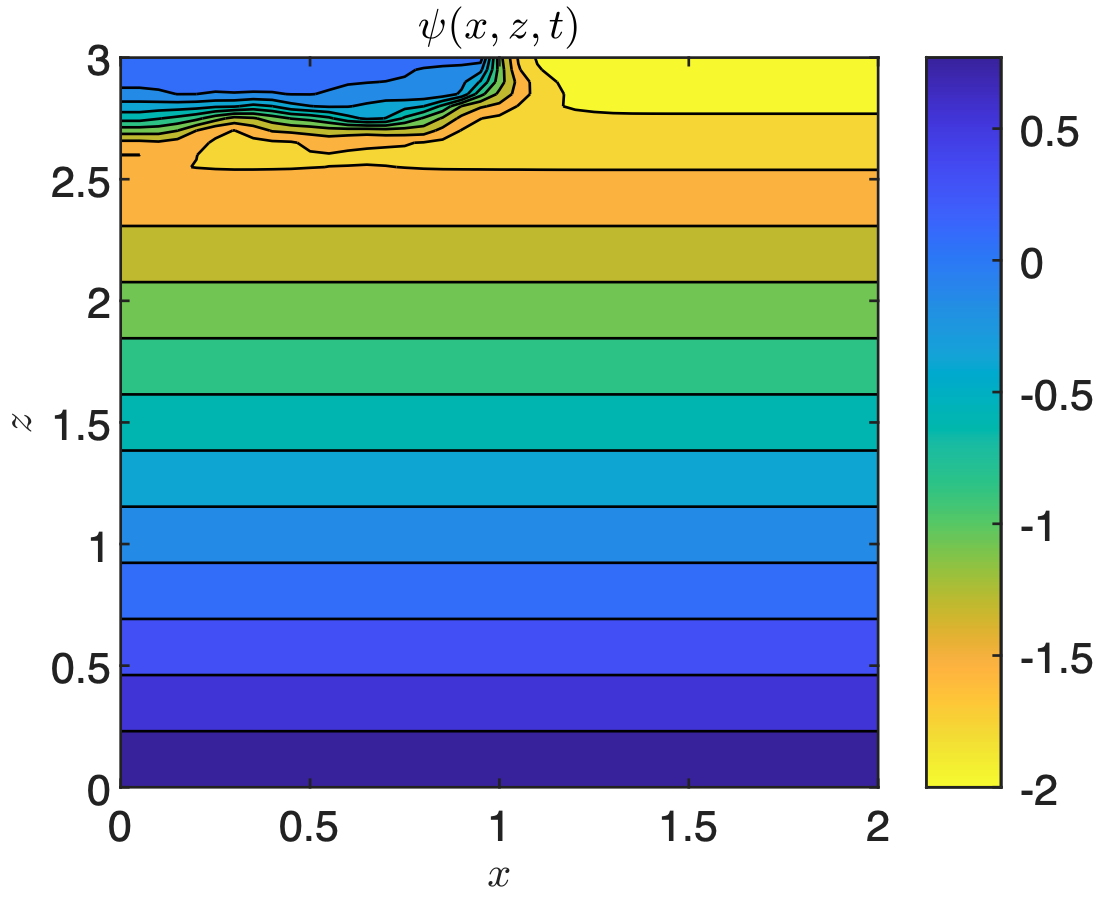

A data-driven modeling approach for water flow dynamics in soilZeyuan Song and Zheyu JiangComputer Aided Chemical Engineering, Jun 2023

A data-driven modeling approach for water flow dynamics in soilZeyuan Song and Zheyu JiangComputer Aided Chemical Engineering, Jun 2023Modeling and predicting soil moisture is essential for precision agriculture, smart irrigation, drought prevention, etc. Estimating root zone soil moisture from surface or near-surface soil moisture data is typically achieved by solving a hydrological model that describes water movement through soils. Advanced agro-hydrological models today use the Richards equation, a highly nonlinear, degenerate elliptic-parabolic partial differential equation that captures irrigation, precipitation, evapotranspiration, runoff, and drainage. State-of-the-art Richards equation solvers employ either a finite difference, finite element, or finite volume discretization framework in space. In this paper, we introduce a novel computational framework to solve generic n-dimensional Richards equation by introducing global random walk and deep neural network to a modified finite volume method (FVM). Furthermore, for n-dimensional Richards equation, we introduce multipoint flux approximation to the FVM framework. Through these innovations, our novel computational framework effectively utilizes the underlying physics behind the Richards equation, which enhances the speed and accuracy of the solution process. Through an illustrative case study, we demonstrate the efficiency and effectiveness of our computational framework and show that it correctly characterizes the physical relationships among soil moisture content, pressure head, and flux.

@article{song:2023:escape, title = {A data-driven modeling approach for water flow dynamics in soil}, journal = {Computer Aided Chemical Engineering}, volume = {52}, pages = {819-824}, year = {2023}, doi = {http://dx.doi.org/10.1016/B978-0-443-15274-0.50131-1}, author = {Song, Zeyuan and Jiang, Zheyu}, month = jun, keywords = {Soil moisture, Richards equation, finite volume method, neural network, random walk}, } - ESCAPE33

Stochastic optimization of agrochemical supply chains with risk managementSaba Ghasemi Naraghi and Zheyu JiangComputer Aided Chemical Engineering, Jun 2023

Stochastic optimization of agrochemical supply chains with risk managementSaba Ghasemi Naraghi and Zheyu JiangComputer Aided Chemical Engineering, Jun 2023The global agrochemical market is highly consolidated, with large multinational companies accounting for a major share of the market. Thus, even for a single agrochemical product, its supply chain typically involves many possible paths connecting the raw material sources of active ingredients to final customers. In addition to structural complexity, agrochemical supply chains are also subject to seasonality and various unique uncertainties, thereby demanding high system resilience and implementation of risk management strategies in the face of these uncertainties and disruptions. In this study, we formulate and optimize the supply chain of an agrochemical active ingredient by formulating a stochastic mixed-integer nonlinear programming (MINLP) model. This MINLP formulation is scenario-based with demand uncertainty addressed by Value-at- Risk (VaR) and Conditional Value-at-Risk (CVaR). For the first time, we propose to reformulate these nonlinear CVaR constraints using perspective reformulation techniques. We show that these perspective cuts give a tight approximation of the original MINLP model. Through an illustrative case study, we compare the results and performance of the original MINLP and the reformulated MILP.

@article{saba:2023:escape, title = {Stochastic optimization of agrochemical supply chains with risk management}, journal = {Computer Aided Chemical Engineering}, month = jun, volume = {52}, pages = {3335-3340}, year = {2023}, doi = {http://dx.doi.org/10.1016/B978-0-443-15274-0.50532-1}, author = {Ghasemi Naraghi, Saba and Jiang, Zheyu}, keywords = {Agrochemical supply chain, Value-at-Risk, Conditional Value-at-Risk, perspective cuts, mixed-integer nonlinear programming}, } - FOCAPO/CPC 2023A Data-Driven Random Walk Approach for Solving Water Flow Dynamics in Soil SystemsZeyuan Song and Zheyu JiangIn Proceedings of Foundations of Computer-Aided Process Operations and Chemical Process Control Conference, Jan 2023

Modeling and predicting soil moisture is essential for precision agriculture, smart irrigation, and drought prevention. In this work, we introduce a novel data-driven random walk (DRW) approach to solve n-dimensional Richards equation, a complex partial differential equation that characterizes water flow dynamics in soil. This advanced computational framework integrates multiple features, including finite volume discretization, adaptive L-scheme, multi-layer neural networks, and the concept of random walk to enable fast and accurate numerical solution of the Richards equation. Through an illustrative example, we demonstrate the accuracy and attractiveness of this novel approach. In particular, we show that our DRW approach can implicitly capture the underlying physical relationships among soil moisture content, pressure head, and flux, which will enable more accurate characterization of water flow dynamics.

@inproceedings{song:2023:richards, author = {Song, Zeyuan and Jiang, Zheyu}, title = {A Data-Driven Random Walk Approach for Solving Water Flow Dynamics in Soil Systems}, booktitle = {Proceedings of Foundations of Computer-Aided Process Operations and Chemical Process Control Conference}, year = {2023}, month = jan, address = {San Antonio, TX}, } - FOCAPO/CPC 2023

A Shortcut Model for Multicomponent Homogeneous Azeotropic DistillationZheyu JiangIn Proceedings of Foundations of Computer-Aided Process Operations and Chemical Process Control Conference, Jan 2023

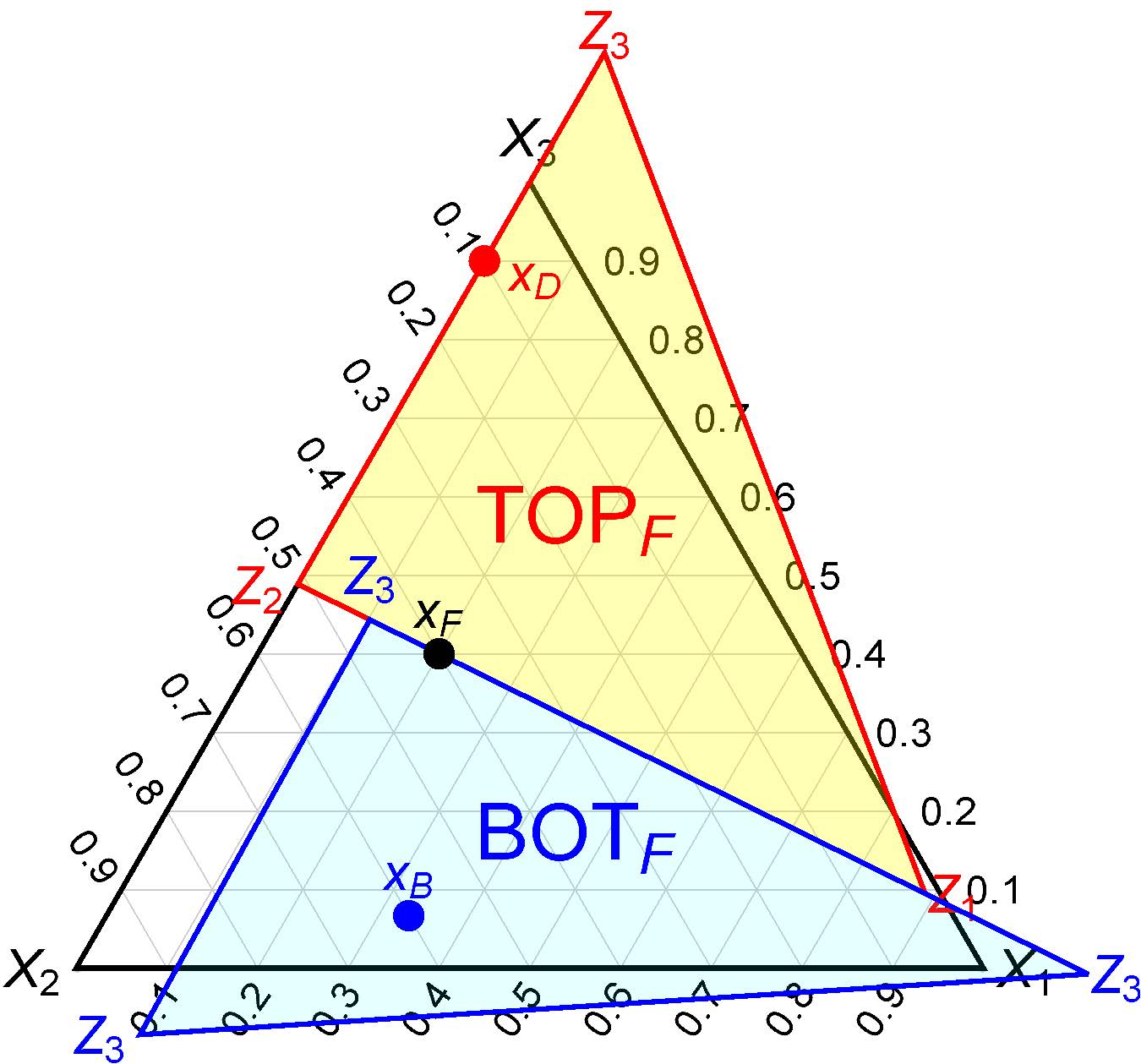

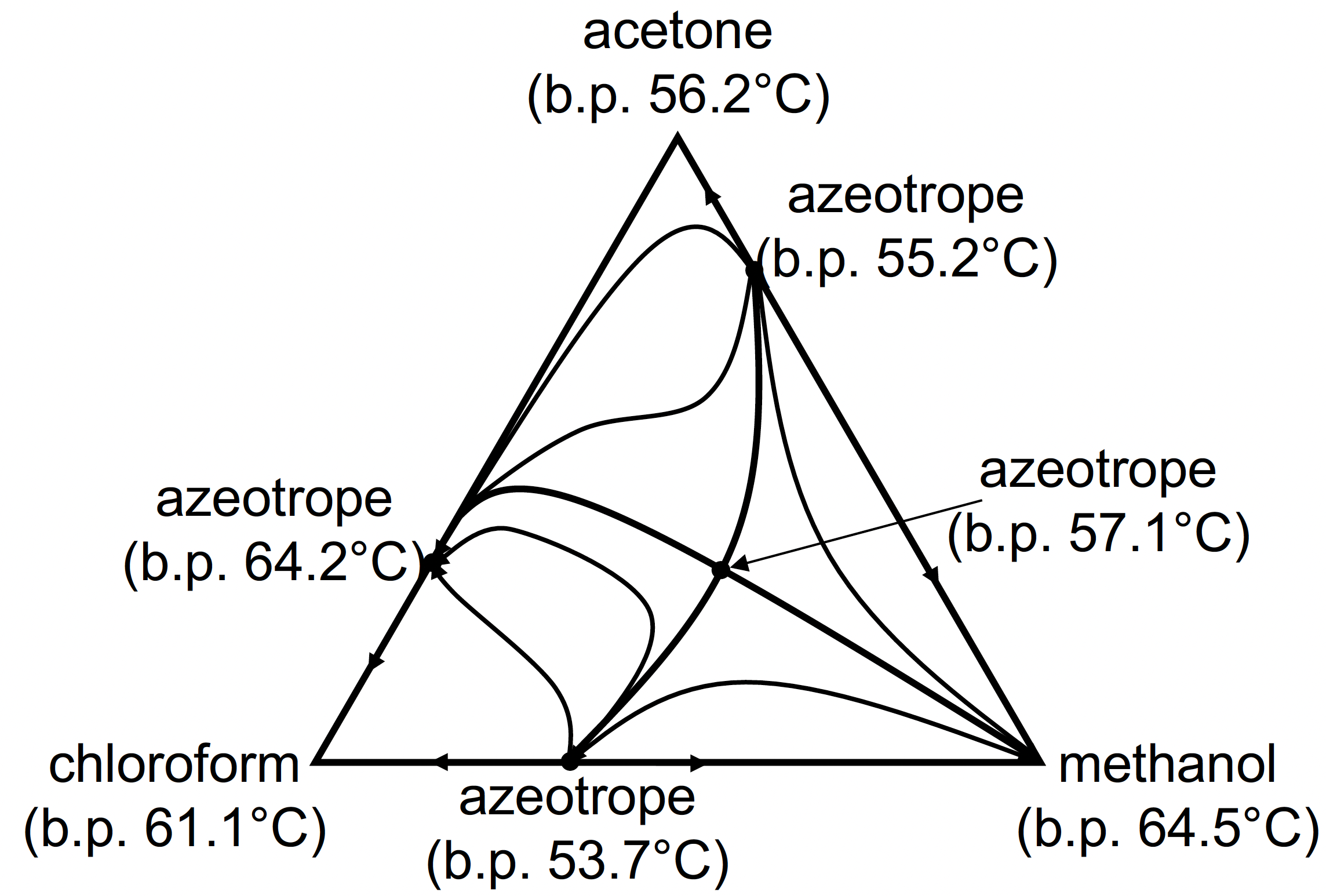

A Shortcut Model for Multicomponent Homogeneous Azeotropic DistillationZheyu JiangIn Proceedings of Foundations of Computer-Aided Process Operations and Chemical Process Control Conference, Jan 2023Distillation of multicomponent mixtures forming one or more azeotropes is ubiquitous in chemical process industries. The minimum reflux ratio of a distillation column is directly related to its energy consumption and capital cost. Thus, it is a key parameter for distillation systems design, operation, and comparison. However, this problem remains an open challenge to researchers and industrial practitioners due to the highly nonideal nature of azeotropic systems. In this work, we present a simple and easy-to-use shortcut method to analytically calculate the minimum reflux ratio for a broad class of multicomponent homogeneous azeotropic mixture separations. Compared with existing techniques, this method does not involve any rigorous tray-by-tray calculation and is iteration free. Through an illustrative example, we demonstrate the accuracy and effectiveness of this new approach.

@inproceedings{jiang:2023:azeotrope, author = {Jiang, Zheyu}, title = {A Shortcut Model for Multicomponent Homogeneous Azeotropic Distillation}, booktitle = {Proceedings of Foundations of Computer-Aided Process Operations and Chemical Process Control Conference}, year = {2023}, month = jan, address = {San Antonio, TX}, } - IISE 2023

Stochastic Optimization of Global Agrochemical Supply Chains with Risk Management: Modeling and ReformulationSaba Ghasemi Naraghi and Zheyu JiangIn Proceedings of 2023 IISE Annual Conference and Expo 2023, May 2023

Stochastic Optimization of Global Agrochemical Supply Chains with Risk Management: Modeling and ReformulationSaba Ghasemi Naraghi and Zheyu JiangIn Proceedings of 2023 IISE Annual Conference and Expo 2023, May 2023The global agrochemical market is highly consolidated, with large multinational companies accounting for a major share of the market. Thus, even for a single agrochemical product, its global supply chain typically involves numerous paths connecting the raw material sources to the final customers. Besides structural complexity, agrochemical supply chains are also subject to seasonality and other unique uncertainties, thereby posing a need for risk management tools and strategies. In this study, we model and optimize an agrochemcial supply chain by developing and solving a stochastic mixed-integer quadratic constrained program (MIQCP). We model and control the demand uncertainty in this scenario-based MIQCP using variance. We also apply perspective reformulation techniques to convert the MIQCP to a mixed-integer linear program (MILP). Computational experiment results from an illustrative example show that, successively introducing perspective cuts to the reformulated MILP not only leads to a tight approximation of the original MIQCP model, but is also more computationally efficient than directly solving the MIQCP.

@inproceedings{saba:2023:iise, author = {Ghasemi Naraghi, Saba and Jiang, Zheyu}, title = {Stochastic Optimization of Global Agrochemical Supply Chains with Risk Management: Modeling and Reformulation}, booktitle = {Proceedings of 2023 IISE Annual Conference and Expo 2023}, year = {2023}, month = may, address = {New Orleans, LA}, eprint = {2401.12348}, archiveprefix = {arXiv}, doi = {https://doi.org/10.48550/arXiv.2401.12348}, } - IISE 2023

The Effect of Different Optimization Strategies to Physics-Constrained Deep Learning for Soil Moisture EstimationJianxin Xie, Bing Yao, and Zheyu JiangIn Proceedings of 2023 IISE Annual Conference and Expo 2023, May 2023

The Effect of Different Optimization Strategies to Physics-Constrained Deep Learning for Soil Moisture EstimationJianxin Xie, Bing Yao, and Zheyu JiangIn Proceedings of 2023 IISE Annual Conference and Expo 2023, May 2023Soil moisture is a key hydrological parameter that has significant importance to human society and the environment. Accurate modeling and monitoring of soil moisture in crop fields, especially in the root zone (top 100 cm of soil), is essential for improving agricultural production and crop yield with the help of precision irrigation and farming tools. Realizing the full sensor data potential depends greatly on advanced analytical and predictive domain-aware models. In this work, we propose a physics-constrained deep learning (P-DL) framework to integrate physics-based principles on water transport and water sensing signals for effective reconstruction of the soil moisture dynamics. We adopt three different optimizers, namely Adam, RMSprop, and GD, to minimize the loss function of P-DL during the training process. In the illustrative case study, we demonstrate the empirical convergence of Adam optimizers outperforms the other optimization methods in both mini-batch and full-batch training.

@inproceedings{xie:2023:iise, author = {Xie, Jianxin and Yao, Bing and Jiang, Zheyu}, title = {The Effect of Different Optimization Strategies to Physics-Constrained Deep Learning for Soil Moisture Estimation}, booktitle = {Proceedings of 2023 IISE Annual Conference and Expo 2023}, year = {2023}, month = may, address = {New Orleans, LA}, pages = {121-126}, }

2022

- AIChE

Minimum Reflux Calculation for Multicomponent Distillation in Multi-Feed, Multi-Product Columns: Mathematical ModelZheyu Jiang, Mohit Tawarmalani, and Rakesh AgrawalAIChE Journal, May 2022

Minimum Reflux Calculation for Multicomponent Distillation in Multi-Feed, Multi-Product Columns: Mathematical ModelZheyu Jiang, Mohit Tawarmalani, and Rakesh AgrawalAIChE Journal, May 2022Multi-feed, multi-product distillation columns are ubiquitous in multicomponent distillation systems. The minimum reflux ratio of a distillation column is directly related to its energy consumption and capital cost. Thus, it is a key parameter for distillation systems design, operation, and comparison. In this series, we present the first accurate shortcut based algorithmic method to determine the minimum reflux condition for any general multi-feed, multi-product (MFMP) distillation column separating any ideal multicomponent mixture. The classic McCabe-Thiele or Underwood method is a special case of this general approach. Compared with existing techniques, this method does not involve any rigorous tray-by-tray calculation, nor does it require guessing of key components. In this first part of the series, we present the mathematical model for a general MFMP column, derive constraints for feasible separation and minimum reflux condition, discuss their geometric interpretations, and present an illustrative example to demonstrate the effectiveness of our approach.

@article{jiang:2022:mfmp1, author = {Jiang, Zheyu and Tawarmalani, Mohit and Agrawal, Rakesh}, title = {Minimum Reflux Calculation for Multicomponent Distillation in Multi-Feed, Multi-Product Columns: {M}athematical Model}, journal = {AIChE Journal}, year = {2022}, volume = {68}, number = {12}, pages = {e17929}, doi = {https://doi.org/10.1002/aic.17929}, eprint = {https://aiche.onlinelibrary.wiley.com/doi/pdf/10.1002/aic.17929}, }

2020

- CVTA

A shortcut minimum reflux calculation method for distillation columns separating multicomponent homogeneous azeotropic mixturesZheyu JiangLe Scientifique, May 2020

A shortcut minimum reflux calculation method for distillation columns separating multicomponent homogeneous azeotropic mixturesZheyu JiangLe Scientifique, May 2020Chemical, pharmaceutical, and agrochemical industries frequently face the challenge of separating multicomponent mixtures exhibiting one or more azeotropes using distillation. The minimum reflux ratio of a distillation column is directly related to its energy consumption and capital cost. Thus, it is a key parameter for distillation systems design, operation, and comparison. Despite its great scientific significance and practical importance, this problem remains an open challenge to researchers and industrial practitioners due to the highly nonideal nature of azeotropic systems. In this work, we present a simple and easy-to-use shortcut method to analytically calculate the minimum reflux ratio for a broad class of multicomponent homogeneous azeotropic mixture separations. Through an illustrative example, we demonstrate the accuracy and effectiveness of our new ideal multicomponent distillation turns out to be a special case of this generalized method. Compared with existing techniques, this method does not involve any rigorous tray-by-tray calculation and is iteration free. Therefore, it can be easily incorporated into a global optimization framework that enables industrial practitioners to, for the first time, quickly synthesize energy-efficient and cost-effective multicomponent azeotropic distillation systems and determine their optimal operating conditions.

@article{jiang:2020:azeotropic, author = {Jiang, Zheyu}, title = {A shortcut minimum reflux calculation method for distillation columns separating multicomponent homogeneous azeotropic mixtures}, journal = {Le Scientifique}, year = {2020}, volume = {2020}, number = {1}, pages = {17-25}, }

2019

- ChERD

Process intensification in multicomponent distillation: A review of recent advancementsZheyu Jiang and Rakesh AgrawalChemical Engineering Research and Design, May 2019

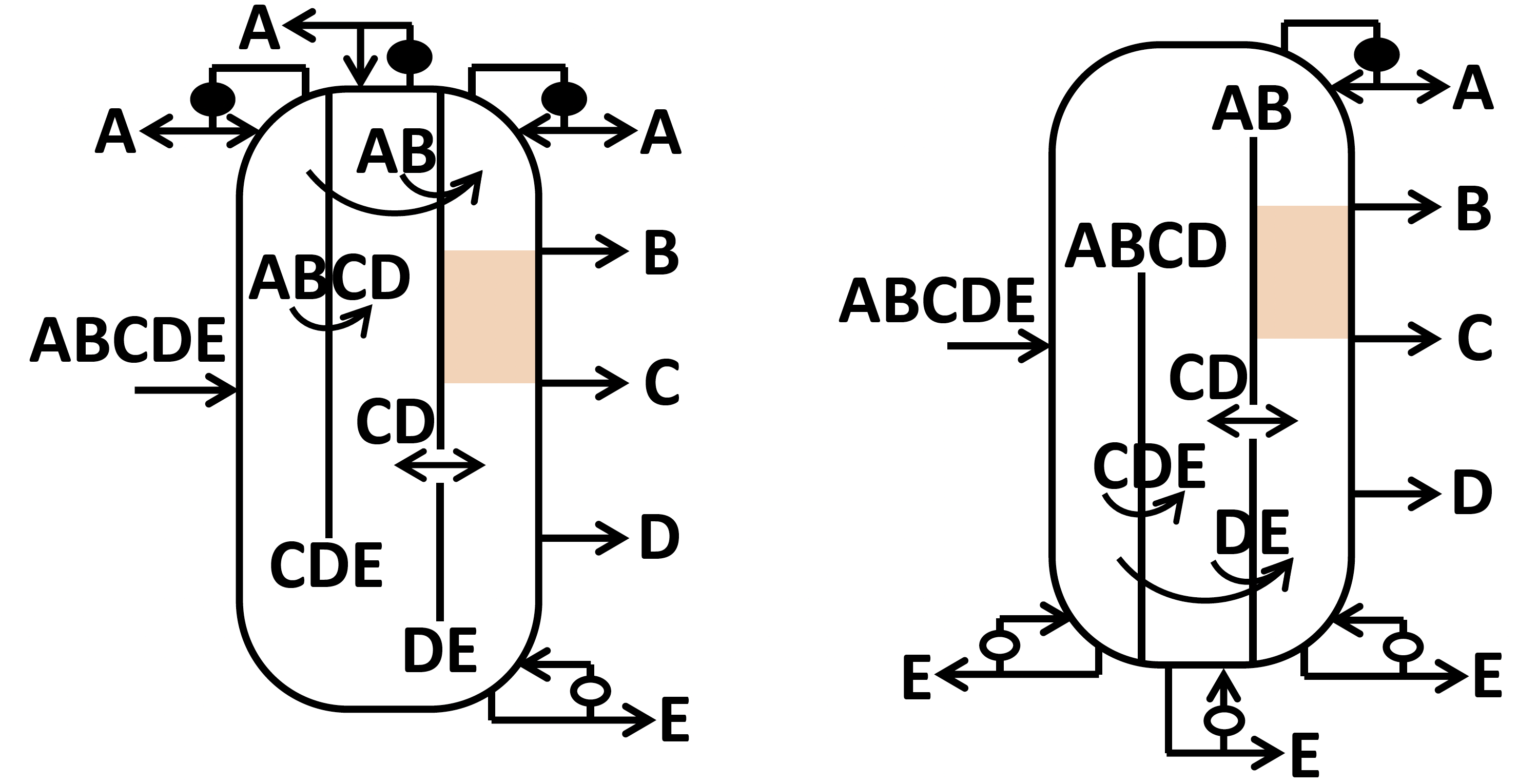

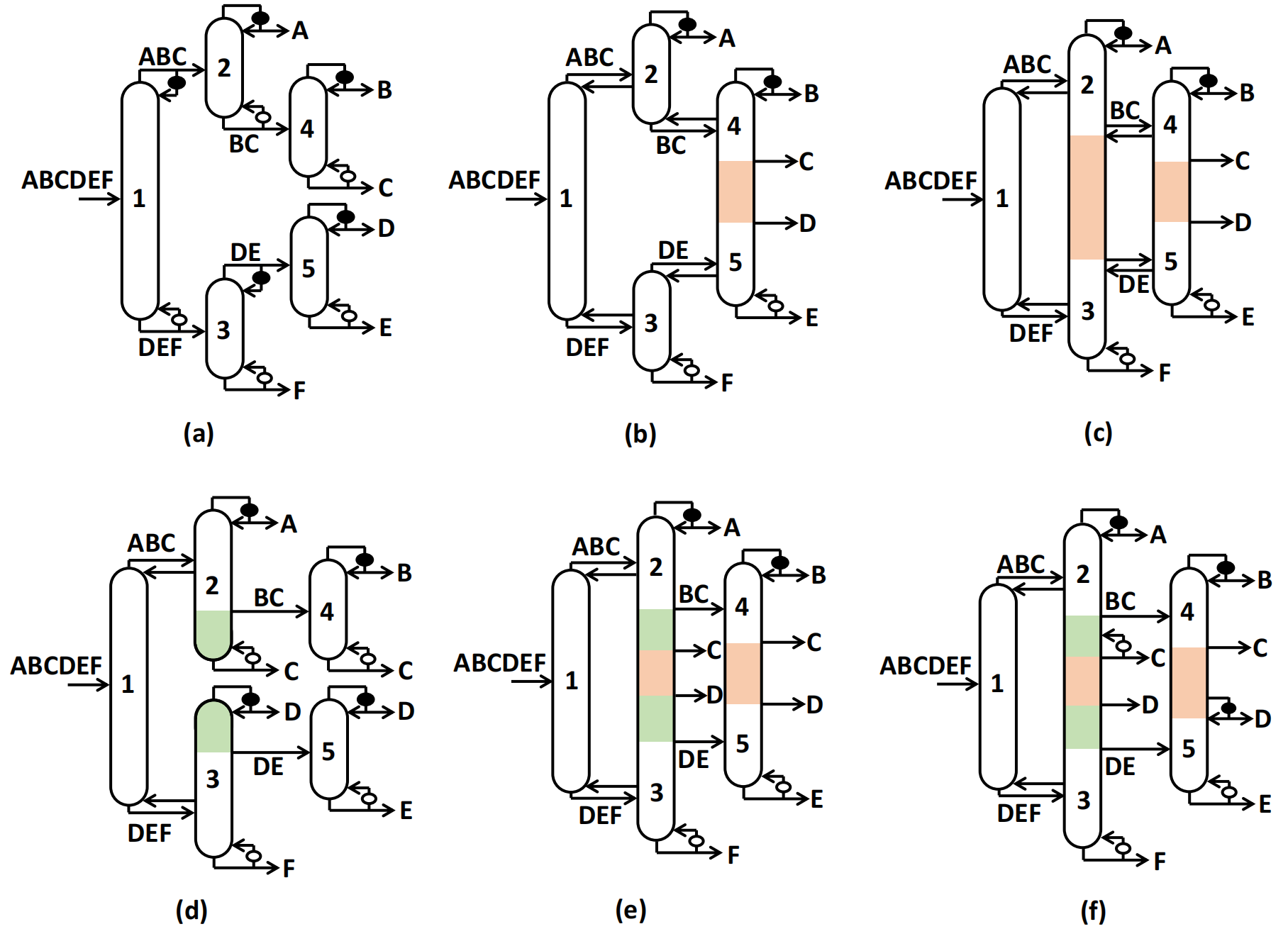

Process intensification in multicomponent distillation: A review of recent advancementsZheyu Jiang and Rakesh AgrawalChemical Engineering Research and Design, May 2019Process intensification (PI) is an emerging concept in chemical engineering that describes the design innovations that lead to significant shrinkage in size and boost in efficiency of a process plant. Distillation, the most commonly used separation technique in the chemical industry, is a crucial component of PI. Here, we systematically discuss the following aspects of PI in non-azeotropic multicomponent distillation: (1) Introducing thermal couplings to eliminate intermediate reboilers and condensers to save energy and capital cost; (2) Improving operability of thermally coupled columns by means of eliminating vapor streams in thermal couplings with only liquid transfers or column section rearrangement; (3) Enabling double and multi-effect distillation of thermally coupled configurations to further reduce heat duty; (4) Performing simultaneous heat and mass integration among thermally coupled columns to reduce the number of columns and heat duty; and (5) Conducting any thermally coupled distillation in n-product streams using 1 to n−2 column shells with operable novel dividing wall columns. We demonstrate these aspects of PI through examples to illustrate how they lead to compact, easy-to-operate, energy efficient and cost effective multicomponent distillation system designs.

@article{jiang:2019:pireview, title = {Process intensification in multicomponent distillation: A review of recent advancements}, journal = {Chemical Engineering Research and Design}, volume = {147}, pages = {122-145}, year = {2019}, issn = {0263-8762}, doi = {https://doi.org/10.1016/j.cherd.2019.04.023}, author = {Jiang, Zheyu and Agrawal, Rakesh}, keywords = {Process intensification, Multicomponent distillation, Separation}, } - CACE

Global optimization of multicomponent distillation configurations: Global minimization of total cost for multicomponent mixture separationsZheyu Jiang, Tony Joseph Mathew, Haibo Zhang, and 4 more authorsComputers & Chemical Engineering, May 2019

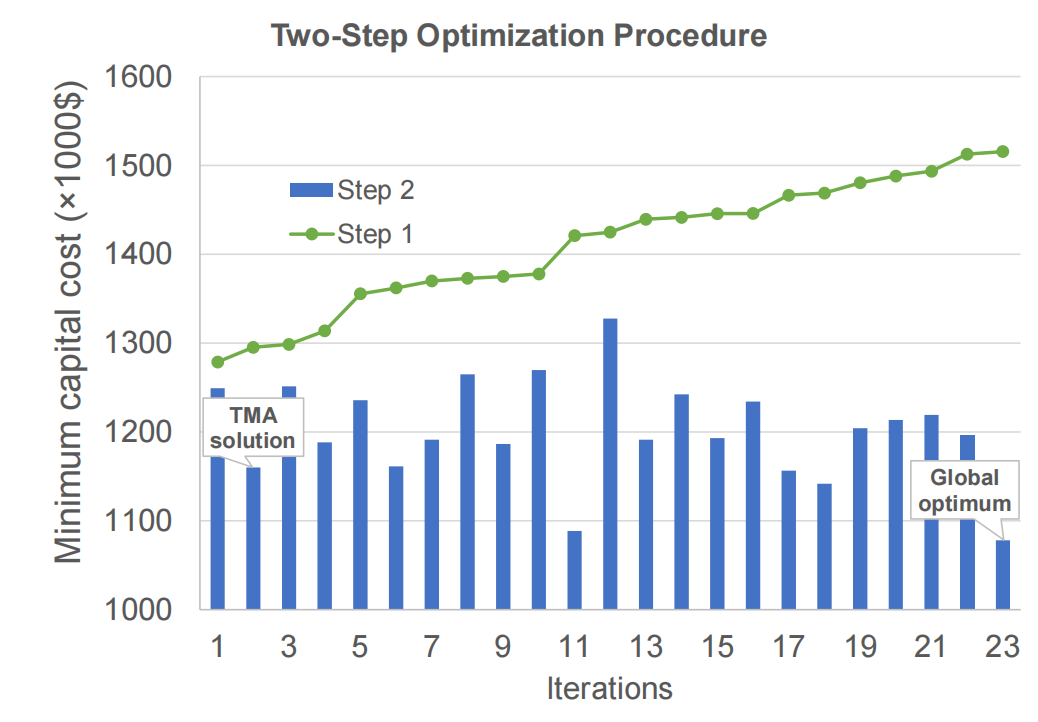

Global optimization of multicomponent distillation configurations: Global minimization of total cost for multicomponent mixture separationsZheyu Jiang, Tony Joseph Mathew, Haibo Zhang, and 4 more authorsComputers & Chemical Engineering, May 2019We introduce a global optimization framework for determining the minimum cost required to distill any ideal or near-ideal multicomponent mixture into its individual constituents using a sequence of columns. This new framework extends the Global Minimization Algorithm (GMA) previously introduced by Nallasivam et al. (2016); and we refer to the new framework as the Global Minimization Algorithm for Cost (GMAC). GMAC guarantees global optimality by formulating a nonlinear program (NLP) for each and every distillation configuration in the search space and solving it using global optimization solvers. The case study presented in this work not only demonstrates the need for developing such an algorithm, but also shows the flexibility and effectiveness of GMAC, which enables process engineers to design and retrofit energy efficient and cost-effective distillation configurations.

@article{jiang:2019:nlpcost, title = {Global optimization of multicomponent distillation configurations: Global minimization of total cost for multicomponent mixture separations}, journal = {Computers & Chemical Engineering}, volume = {126}, pages = {249-262}, year = {2019}, issn = {0098-1354}, doi = {https://doi.org/10.1016/j.compchemeng.2019.04.009}, author = {Jiang, Zheyu and Mathew, Tony Joseph and Zhang, Haibo and Huff, Joshua and Nallasivam, Ulaganathan and Tawarmalani, Mohit and Agrawal, Rakesh}, keywords = {Multicomponent distillation, Distillation configuration, Global optimization, Cost optimization, Process intensification}, } - AIChE

Global minimization of total exergy loss of multicomponent distillation configurationsZheyu Jiang, Zewei Chen, Joshua Huff, and 3 more authorsAIChE Journal, May 2019

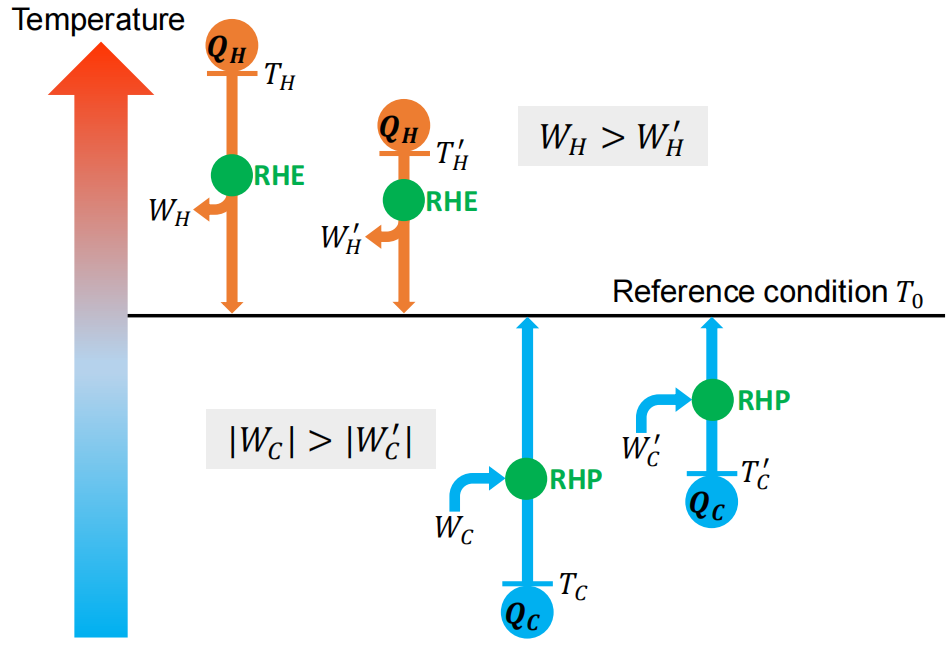

Global minimization of total exergy loss of multicomponent distillation configurationsZheyu Jiang, Zewei Chen, Joshua Huff, and 3 more authorsAIChE Journal, May 2019The operating cost of a multicomponent distillation system comprises two major aspects: the overall heat duty requirement and the temperature levels at which the heat duties are generated and rejected. The second aspect, often measured by the thermodynamic efficiency of the distillation system, can be quantified by its total exergy loss. In this article, we introduce a global optimization framework for determining the minimum total exergy loss required to distill any ideal or near-ideal multicomponent mixture using a sequence of columns. Desired configurations identified by this new framework tend to use milder-temperature reboilers and condensers and are thus attractive for applications such as heat pump assisted distillation. Through a case study of shale gas separations, we demonstrate the effectiveness of this framework and present various useful physical insights for designing energy efficient distillation systems.

@article{jiang:2019:nlpexergy, author = {Jiang, Zheyu and Chen, Zewei and Huff, Joshua and Shenvi, Anirudh A. and Tawarmalani, Mohit and Agrawal, Rakesh}, title = {Global minimization of total exergy loss of multicomponent distillation configurations}, journal = {AIChE Journal}, volume = {65}, number = {11}, pages = {e16737}, keywords = {distillation configuration, exergy analysis, global optimization, multicomponent distillation, thermodynamic efficiency}, doi = {https://doi.org/10.1002/aic.16737}, eprint = {https://aiche.onlinelibrary.wiley.com/doi/pdf/10.1002/aic.16737}, year = {2019}, }

2018

- AIChE

Minimum energy of multicomponent distillation systems using minimum additional heat and mass integration sectionsZheyu Jiang, Gautham Madenoor Ramapriya, Mohit Tawarmalani, and 1 more authorAIChE Journal, May 2018

Minimum energy of multicomponent distillation systems using minimum additional heat and mass integration sectionsZheyu Jiang, Gautham Madenoor Ramapriya, Mohit Tawarmalani, and 1 more authorAIChE Journal, May 2018Heat and mass integration to consolidate distillation columns in a multicomponent distillation configuration can lead to a number of new energy efficient and cost-effective configurations. In this work, a powerful and simple-to-use fact about heat and mass integration is identified. The newly developed heat and mass integrated configurations, which we call as HMP configurations, involve first introducing thermal couplings to all intermediate transfer streams, followed by consolidating columns associated with a lighter pure product reboiler and a heavier pure product condenser. A systematic method of enumerating all HMP configurations is introduced. The energy savings of HMP configurations is compared with the well-known fully thermally coupled (FTC) configurations. HMP configurations can have very similar and sometimes even the same minimum total vapor duty requirement as the FTC configuration is demonstrated, while using far less number of column sections, intermediate transfer streams, and thermal couplings than the FTC configurations.

@article{jiang:2018:hmp, author = {Jiang, Zheyu and Madenoor Ramapriya, Gautham and Tawarmalani, Mohit and Agrawal, Rakesh}, title = {Minimum energy of multicomponent distillation systems using minimum additional heat and mass integration sections}, journal = {AIChE Journal}, volume = {64}, number = {9}, pages = {3410-3418}, keywords = {multicomponent distillation, distillation sequences, distillation configurations, heat and mass integration, process intensification}, doi = {https://doi.org/10.1002/aic.16189}, eprint = {https://aiche.onlinelibrary.wiley.com/doi/pdf/10.1002/aic.16189}, year = {2018}, } - DA 2018

Process Intensification in Multicomponent DistillationZheyu Jiang, Gautham Madenoor Ramapriya, Mohit Tawarmalani, and 1 more authorChemical Engineering Transactions, May 2018

Process Intensification in Multicomponent DistillationZheyu Jiang, Gautham Madenoor Ramapriya, Mohit Tawarmalani, and 1 more authorChemical Engineering Transactions, May 2018Process Intensification (PI) is an emerging concept in chemical engineering which describes the design innovations that lead to significant shrinkage in size and dramatic boost in efficiency in a process plant. Distillation, which is one of the most important separation technologies in the chemical industry, is therefore a crucial component in PI. Here, we discuss two aspects of PI in multicomponent distillation: 1) Performing simultaneous heat and mass integration among thermally coupled distillation columns to reduce the number of columns and heat duty requirement; and 2) Conducting any thermally coupled distillation in only a single column shell using a dividing wall column that is fully operable. Through examples, we show that synergistic use of both strategies leads to the design of compact, easy-to-operate, energy efficient and cost effective multicomponent distillation systems.

@article{jiang:2018:piconference, author = {Jiang, Zheyu and Madenoor Ramapriya, Gautham and Tawarmalani, Mohit and Agrawal, Rakesh}, title = {Process Intensification in Multicomponent Distillation}, journal = {Chemical Engineering Transactions}, volume = {69}, pages = {841-846}, doi = {10.3303/CET1869141}, year = {2018}, }

2013

- AIChESolution-processable exfoliated zeolite nanosheets purified by density gradient centrifugationKumar Varoon Agrawal, Berna Topuz, Zheyu Jiang, and 5 more authorsAIChE Journal, May 2013

Highly crystalline exfoliated MFI-nanosheets can pave the way for large-scale deployment of sub-500-nm zeolite membranes due to their processing and packing advantages. Exfoliated MFI-nanosheets prepared by melt compounding contain a large amount of polymer and unexfoliated particles which are detrimental to the fabrication of ultrathin zeolite membranes. Complete removal of polystyrene from the nanosheet suspension in toluene is demonstrated by centrifugation of the suspension across chlorobenzene as confirmed by thermogravimetric analysis (TGA) data and transmission electron microscopy (TEM) images. Rate-zonal centrifugation in a nonlinear density gradient fractionated exfoliated MFI-nanosheets from unexfoliated particles. The purified nanosheets were highly crystalline as indicated by high-resolution TEM (HRTEM) and electron diffraction (ED). Coating of purified MFI-nanosheets on a smooth α-alumina support, fabricated by filtration of α-alumina suspension, led to a compact, b-oriented, 80-nm-thick film. A mild hydrothermal treatment of the film led to a 200-nm-thick membrane, which demonstrated molecular sieving properties.

@article{kumar:2013:zeolite, author = {Agrawal, Kumar Varoon and Topuz, Berna and Jiang, Zheyu and Nguenkam, Kevin and Elyassi, Bahman and Francis, Lorraine F. and Tsapatsis, Michael and Navarro, Marta}, title = {Solution-processable exfoliated zeolite nanosheets purified by density gradient centrifugation}, journal = {AIChE Journal}, volume = {59}, number = {9}, pages = {3458-3467}, keywords = {zeolite nanosheets, density gradient centrifugation, zeolite membrane, membrane support}, doi = {https://doi.org/10.1002/aic.14099}, eprint = {https://aiche.onlinelibrary.wiley.com/doi/pdf/10.1002/aic.14099}, year = {2013}, }